Dry Scroll vacuum pumps

Dry Scroll vacuum pump’s features and maintenance

Features of scroll-type pumps – low vibration, low noise and high efficiency!

The dry scroll vacuum pumps are used in various vacuum environments, ranging from the accelerator market to the general-purpose vacuum device market.

These pumps provide clean vacuum without back-diffusion of lubricating oil.

They endure repeated continuous operation between atmospheric pressure and vacuum and are capable of continuous operation near atmospheric pressure.

These features make the pumps best-selling models.

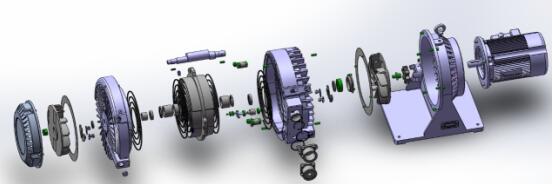

The processes of suction, compression and exhaust proceed continuously with little change in torque, resulting in low vibration and low noise.

The suction chamber and exhaust chamber are not adjacent to each other, making the pumps less prone to leaks and highly efficient.

Dry Scroll vacuum pump application:

1.Sputtering equipment, vacuum deposition equipment, ion plating equipment

2.Accelerator

3.Surface modification, electron beam process

4.Vacuum furnace, vacuum heat treatment furnace

5.Gas circulation and recovery devices

6.Laboratory experiments and analyzers

7.Vacuum Pump system

8.He leak detector

9.Vacuum vacuum chuck

10.Vacuum packaging machine

11.Others

Dry Scroll vacuum pump maintenance:

1.Since the pumps do not use cooling water or lubricating oil, they are easy to install and maintain.

2.There is no need to inspect and replace oil filters, lubricating oil, etc.

3.This vacuum pumping system is suitable for clean processes only

Do not use toxic, explosive, flammable or corrosive substances or substances which contain chemicals, solvents or particles. Use at ambient temperature in the range of 10℃ to 40℃

If you want to know more about our vacuum pump products, or if you want to consult the dry scroll vacuum pump please leave a message or send us an email at contact@evpvacuum.com

Keywords: vacuum pump ; dry scroll vacuum pump; dry pump

Edited by: Annie Hou / Shanghai EVP Vacuum Technology Co., Ltd.