EVP Liquid Ring Vacuum Pumps: Core Power for Seawater Deaeration Towers, Leading the New Paradigm of High Efficiency and Energy Saving

In the fields of marine engineering, offshore oil and gas development, and industrial water treatment, seawater deaeration technology is a key link to ensure equipment safety and extend system lifespan. Seawater deaeration towers remove dissolved oxygen and corrosive gases from water to effectively prevent pipeline corrosion and microbial growth. As the core equipment for creating a vacuum environment inside the tower, liquid ring vacuum pumps directly determine deaeration efficiency and operational stability. The EVP DLV series liquid ring vacuum pumps have become the preferred supporting solution for seawater deaeration towers due to their precise adaptability and outstanding performance, bringing efficient, energy-saving, and reliable vacuum solutions to the industry.

The core principle of seawater deaeration is based on Henry’s Law, which requires a vacuum pump to reduce the pressure inside the tower to a vacuum range of 0.008-0.02MPa, enabling gas desorption from seawater at 45-65℃. This process imposes strict requirements on the vacuum pump’s pressure stability, corrosion resistance, and energy efficiency, and the working principle of liquid ring vacuum pumps is perfectly suited to this demand: Driven by a motor, the impeller rotates at high speed, causing the working fluid in the pump body (special coolant resistant to salt spray is usually used for seawater scenarios) to form a rotating liquid ring that adheres closely to the pump casing. Periodically changing sealed chambers are formed between the impeller and the liquid ring — when the chamber moves from the suction port to the center of the impeller, its volume gradually expands to create a vacuum, thereby sucking in the gas from the deaeration tower; as the impeller continues to rotate, the volume of the chamber gradually shrinks, and the compressed gas is discharged from the exhaust port. This ultimately achieves continuous and stable vacuum suction and discharge, providing the necessary low-pressure environment for seawater deaeration.

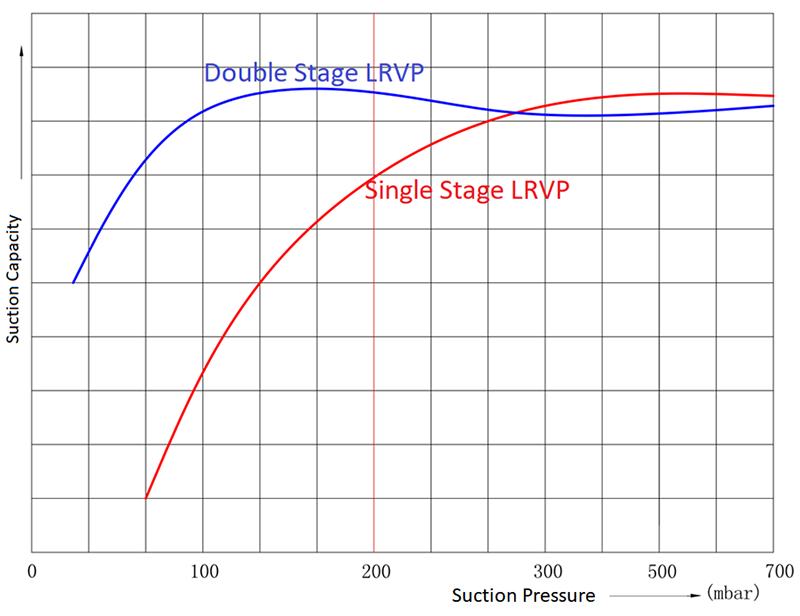

The EVP DLV series liquid ring vacuum pumps have undergone technical upgrades based on traditional principles, adopting a two-stage impeller compression design with an ultimate vacuum of up to 1.0 Inch Hg (33 mbar). Under high vacuum conditions, the gas flow attenuation is reduced by 25%, and energy consumption is saved by approximately 20% compared to traditional equipment, perfectly matching the demand for a continuous and stable vacuum environment in seawater deaeration towers. Equipped with Super Duplex Stainless Steel (UNS S32750), the series can withstand the strong corrosiveness of seawater medium. Combined with the API 681 double-support structure, it effectively resists the impact of harsh marine conditions such as high humidity and vibration, ensuring long-term reliable operation of the equipment.

Typical Application Cases: Technical Adaptation and Value Implementation

Seawater Injection Deaeration Project for Mobile Offshore Production Unit (MOPU)

A national oil company’s seawater injection deaeration project for Mobile Offshore Production Unit (MOPU) selected 2 sets of EVP DLV-800 two-stage liquid ring vacuum pumps to form a vacuum system. The system extracts an average of 66,000 barrels of seawater per day from below the MOPU, first removing 95% of particles of 2 microns and above through an automatic backwash coarse filter and an automatic wash fine filter; the filtered seawater then enters the deaeration tower, achieving deep deaeration with oxygen content below 10ppb under the action of the vacuum pump, and the final deaerated water is injected into Well D-18 at a pressure of 1400psig. The project has extremely high requirements for the pressure stability of the vacuum system (needing to be controlled at 76mbar A) and only requires a pumping speed of 450m³/h. The EVP DLV-800 vacuum pump adopts Super Duplex Stainless Steel (UNS S32750) material and enhanced sealing design, which not only passed the third-party certification of Bureau Veritas (BV, France) but also demonstrated excellent environmental adaptability in actual operation. Against the high vibration and high salt spray conditions of the platform, the equipment has operated stably for more than 9 years, with a maintenance cycle extended by 60% compared to traditional solutions, continuously ensuring the continuity of oil extraction operations.

As a professional brand specializing in vacuum technology, EVP has always been guided by industry needs. Its DLV series of high-efficiency two-stage liquid ring vacuum pumps cover a gas flow range of 110-1600 m³/h for regular models, with a maximum of 4500 m³/h for special models. The motor power ranges from 3.0kW to 75kW, and the maximum specification can be extended to 160kW, which can accurately match various needs from small-scale test devices to large-scale industrial seawater deaeration systems.

In the future, EVP will continue to promote technological innovation, focus on the energy-saving and intelligent needs of the seawater treatment field, provide more competitive vacuum solutions for the global marine engineering and water treatment industries, and help the industry achieve green and low-carbon development.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)