How to choose vacuum pump for vacuum drying

Vacuum drying, also known as analytical drying, is a method of drying materials by placing them under negative pressure and heating them to boiling point properly under negative pressure, or cooling them to solidify them, and then drying them through melting point.

Vacuum drying technology has been widely used in the production of health food, especially in the drying of natural product extracts. Vacuum drying is widely used because many functional components in natural products are not resistant to high temperature.

Moisture in material

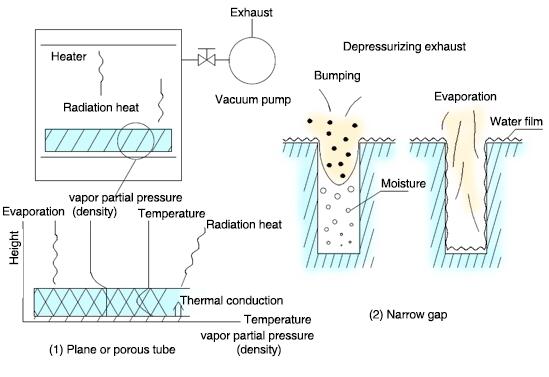

Under negative pressure, the boiling point of melting point decreases with the increase of vacuum degree. At the same time, the content of water vapor is reduced by vacuuming the gap of vacuum pump, so that the water and other solutions in the material can obtain enough kinetic energy to separate from the surface of the material. Vacuum drying can isolate the air under negative pressure, so some materials that are prone to chemical changes (such as oxidation) in the drying process can better maintain their original characteristics, and the materials can be better protected by injecting inert gas and vacuumizing. Common vacuum drying equipment includes: vacuum drying oven, continuous vacuum drying equipment, etc.

vacuum drying principle

All kinds of heating and drying methods under normal pressure will lead to certain loss of color, fragrance, taste and nutrients of materials due to heating. If vacuum drying method is used, some materials that are prone to chemical changes such as oxidation can better maintain their original characteristics and reduce the quality loss due to the isolation of air under negative pressure. Vacuum drying refers to putting the dried food materials into a closed drying chamber, while vacuuming the vacuum system, heating the dried materials properly and continuously, so that the water in the materials diffuses to the surface through the pressure difference or concentration difference, the water molecules obtain enough kinetic energy on the surface of the materials, overcome the attraction between the molecules, escape to the low-pressure air in the vacuum chamber, and Discharged by vacuum pump. There are various vacuum drying methods. Basically, they can be divided into two types: boiling point and melting point.

vacuum drying main characteristics

(1) Vacuum drying is suitable for heat sensitive materials, or materials that are easy to oxidize under high temperature, or valuable, toxic or flammable materials of waste gas.

(2) The range of vacuum degree and heating temperature used for drying is large, with good universality.

(3) Low drying temperature, no overheating, easy evaporation of water, short drying time,

(4) Reduce the chance of contact between materials and air, and avoid pollution or oxidation deterioration.

(5) The dried product can form a porous structure, crisp and porous, easy to crush, with good solubility, rehydration, and good color and taste.

(6) Volatile liquid can be recovered, but the production capacity is small, intermittent operation is needed, and the drying speed is fast.

(7) Equipment investment and power consumption are higher than atmospheric hot air drying.

Selection of drying vacuum degree of work in progress

Generally, vacuum drying and distillation are carried out in low vacuum area.

The freeze-drying process of food is in the middle vacuum zone.

Freeze dried blood and other biological products and high vacuum molecular distillation.

In vacuum drying, high vacuum is conducive to the evaporation of water at a lower temperature, but high vacuum is not conducive to heat conduction and affects the heating effect of materials. High vacuum is conducive to water evaporation from the inside, such as cable through the vacuum differential pressure gap. However, high vacuum will lead to complex vacuum system structure and increase equipment investment.

Therefore, in consideration of the advantages and disadvantages of vacuum and the influence on heat transfer, the vacuum degree of vacuum evaporation drying must be selected appropriately, and the higher the vacuum is, the better it is. For some special materials, low moisture content is required, and there is a process to improve the drying effect by increasing vacuum.

vacuum pump selection

Oil lubricated vane vacuum pump

Oil lubricated vane vacuum pump is widely used in cleaning system. Experience shows that this type of vacuum pump is very suitable for this application, so it has become the standard pump in the drying process of cleaning system. Rotary vane vacuum pump is a kind of high vacuum generator with long service life and high vacuum degree. However, when it comes to cleaning processes with a high probability of steam generation, rotary vane vacuum pumps are not always able to prevent steam condensation during suction and removal of vacuum pumps. At the same time, condensate emulsion vacuum pump oil. This may result in insufficient lubrication of the rolling bearings and discs, wear of other parts of the vacuum pump, and possible effects on suction performance and expected vacuum. These effects can result in more frequent damage to vacuum pump oil and filters, resulting in increased maintenance and overall operating costs.

The dry screw vacuum pump can adapt to the very humid environment, does not need the working fluid, is the ideal choice of the drying process. Because no working fluid is required, the possibility of contamination of the processed material is avoided.

In the dry screw vacuum pump, the rotating direction of the twin-screw rotors in the cylinder is opposite, and they do not contact each other or the inner wall of the cylinder. Similarly, the seal passes through a non-contact mode, so there is no wear. If the steam condenses in the dry screw vacuum pump during compression, it will still be pushed to the exhaust side of the compression chamber by the air flow for removal. Therefore, the volume of several liters of liquid per hour can pass through the pump body without any problem. The discharge outlet is designed to discharge the condensed liquid easily even when the vacuum pump stops.

Unlike rotary vane vacuum pump, screw vacuum pump is water-cooled. The carefully designed cooling principle ensures the absolute uniform and stable temperature of the whole pump body. The amount of coolant can be adjusted by the average value of constant temperature value, which allows the vacuum pump to have ideal temperature control in the process, and avoids unnecessary waste of water resources. In addition, vacuum pump (heat exchanger) with sealed cooling system can also be installed on local equipment without coolant.

vacuum pumps comparison

Both screw technology and rotating plate technology can meet the special requirements of drying process. For the cleaning system with relatively low condensation risk, rotary vane vacuum pump is a wise choice to reduce the procurement cost. However, if the effect of condensation leads to an increase in service and maintenance costs, screw vacuum pumps can save overall costs faster and more profitably. Before making the decision to buy vacuum pump, welcome to the company for consultation.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)