Liquid ring vacuum pump characteristic curve

Liquid ring vacuum pump of description of the characteristic curve

For different types of Liquid ring vacuum pumps, the suction volume flow curve is related to the size of the suction chamber and the suction port of the Liquid ring pump. When the inspiratory volume is relatively small, as the inspiratory pressure increases, the inspiratory volume flow will fill the whole large inspiratory pressure when the inspiratory pressure increases to a certain value, and the inspiratory volume flow will remain unchanged. When the inspiratory pressure increases to a certain value, the inspiratory pressure in the inspiratory cavity is bound to increase, resulting in the inspiratory volume flow.

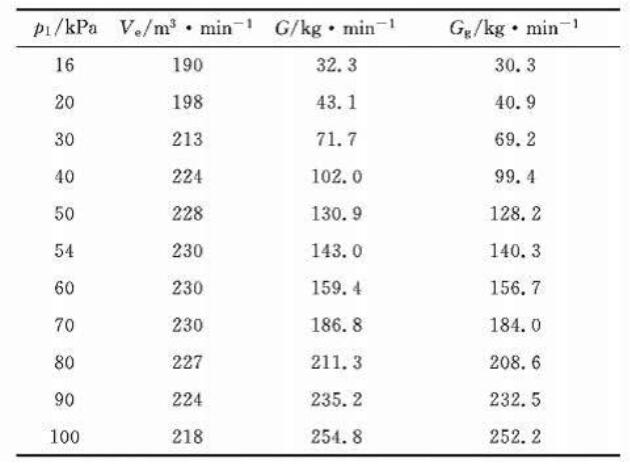

Table 1 suction flow of Liquid ring vacuum pump

During the operation of the Liquid ring pump, the suction temperature, the working water temperature and the suction chamber remain unchanged. As can be seen from the gas state equation pV=mKT, the suction mass flow rate and suction pressure basically form

P1 / p ‘1 material m1 / m 1

According to the relationship between inspiratory mass flow and inspiratory volume flow, with the increase of inspiratory pressure, inspiratory volume flow began to increase and then gradually decreased.

Necessity of gas drainage pump for gas-bearing mine

In recent years, there have been many mine accidents in China, among which a large part is caused by gas explosion. Because of the limitation of mine space, the consequence of a gas explosion is very serious. In general mines, especially coal mines, gas will be emitted from coal strata. When the gas concentration reaches the limit of gas explosion, that is, between 5% and 16%, the explosive power is quite strong. After the explosion will produce a strong airflow, product casualties and damage to pipes and equipment in underground mines. A good way to avoid such accidents is to reduce the concentration of gas. At present, the best way to reduce the gas in the mine is ventilation. However, due to the limitation of mine physical structure, forced ventilation by equipment is necessary to achieve the effect. One way is to use equipment to vacuum pump gas out of mines .

In recent years, our company has designed and developed a variety of types of gas extraction vacuum pumps and mobile gas extraction vacuum pump stations. A large number of domestic coal mines have installed the gas extraction vacuum pumps of our company to ensure the normal and safe production of coal mines. If you have more questions or Suggestions, please call our company for consultation.

Liquid ring vacuum pump of daily inspection and maintenance

1). Vacuum pumps and auxiliary systems

(1) check whether the vacuum pump has abnormal vibration and noise

(2) check whether the bearing temperature is normal

(3) check whether the dynamic seal leakage meets the requirements.

(4) check whether the cooling water is normal.

(5) check whether the static sealing point is leaking.

(6) if there are impurities in the liquid in the vacuum pump, after stopping the vacuum pump, open the bottom valve of the vacuum pump to flush.

(7) regularly open the observation hole on the side cover to check the conditions in the vacuum pump.

(8) lithium base grease zl-3 is used for the grease. Replace the grease after 2000 hours of operation.

2). Process system

(1) check whether the vacuum pump outlet pressure is normal and stable

(2) check whether there is serious vibration in the pipeline

(3) other standby vacuum pumps shall be turned as required