Liquid ring vacuum pump industry

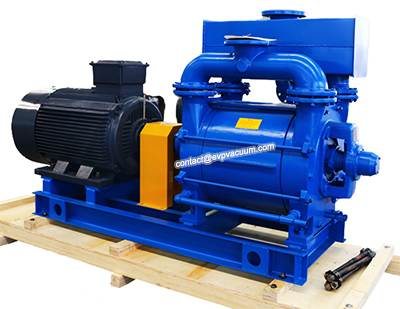

Liquid ring vacuum pump has the characteristics of simple structure, easy to use and maintenance, so it has been widely used in all walks of life. In particular, it has the characteristics of isothermal compression, easy to vacuum pump and compress flammable and explosive gas. The following on its industry development and design development to talk about a few shallow views.

It should be said that before the year 2000, domestic manufacturers of liquid ring vacuum pumps are almost all based on the sale of single vacuum pumps, few users order complete sets of equipment, and in the last two years, the chemical industry, pharmaceutical industry equipment bidding equipment accounted for a growing proportion of complete sets of equipment, is generally required with separators, coolers (heat exchangers), rehydrating vacuum pumps, valves, meters, pipe fittings and control devices, forming a closed cycle, and requires the enterprise’s OCS system connected to the level, pressure, force online control.

The requirement of this complete set of mechanical and electrical integration equipment is becoming more and more common in many industries. Under high vacuum require large swept volume many chemical industry, pharmaceutical industry, vacuum distillation, concentration, dehydration, drying and pumping exhaust power plants require that between the suction pressure is 3-8 kpa have large swept volume, single stage extraction liquid ring vacuum pump in this interval ability is weak, and two levels of liquid ring vacuum pumps and two stage with primary air ejector characteristic of liquid ring vacuum pump is in the region have greater inspiratory capacity, demand for the two stage vacuum pump before 2000 is mostly under 15 m3 / min, and now 40-50 m3 / min. In addition, it should be pointed out that single stage liquid ring vacuum pump with a first stage air ejector, if the design is reasonable, when the suction pressure is 4–5kPa, there is still a large amount of air pumping, which greatly expanded the use of single stage liquid ring vacuum pump, such as China’s aircraft research institute to use this type of vacuum pump.

To sum up, it can be seen that liquid ring vacuum pumps and liquid ring compressors, as basic coarse and low vacuum acquisition equipment, have been widely used in various industries. It can also be said that the rapid development of various industries in the national economy has promoted the development and production of liquid ring vacuum pumps and liquid ring compressors.

Therefore, in order to make it better adapt to the development of various industries, now on the development of the vacuum pump put forward the following points of view.

(1) with the feasibility of the design and high performance seals, improve the whole machine MTBF liquid ring vacuum pump and the working reliability of the liquid ring compressor, that is, the average trouble-free operation period, should be said to be higher than other coarse and low vacuum equipment, the average trouble-free operation period can reach more than 10,000 hours.

However, with the technical progress of various industries and the improvement of the reliability of the whole vacuum system, the reliability requirements are correspondingly higher. Especially in the chemical industry and coal mine gas extraction of such strict safety requirements under the working conditions, the vacuum pump to a long-term continuous operation, the international advanced level can reach tens of thousands of hours. Therefore, the development of the design of liquid ring vacuum pump and liquid ring compressor and the limitation of manufacturing conditions as well as the quality status of seals (especially mechanical seals), in order to really improve the reliability of the whole machine needs to be further strengthened in the above aspects.

(2) adopt optimization design method to improve vacuum pump efficiency and reduce energy consumption

Liquid ring vacuum pump and liquid ring compressor are high energy consumption, low efficiency of the product, this is a recognized fact, small vacuum pump is generally 30-35%, large vacuum pump up to 40% or slightly higher, so low efficiency and the national requirements for mechanical and electrical products and the current situation of China’s energy shortage is very inconsistent. So as soon as possible using optimization design method, the influence of vacuum pump efficiency is the key of the geometric parameters of the impeller and the original position of the suction vent, area set up mathematical model of optimization design, choose the optimal combination parameter of each scheme, and using the theory of gas-liquid two phase flow and the calculation formula for design, to reduce the eddy current loss of liquid ring as far as possible, achieve the purpose of improving efficiency.

Therefore, it is an important task for the design, development and production of liquid ring vacuum pumps to design and develop efficient and energy-saving liquid ring vacuum pumps and compressors as soon as possible to eliminate the backward products with high energy consumption and low efficiency.

3) increase the gas volume at the operating point with the atmospheric ejector

Abroad in any single stage liquid ring vacuum pump or two levels of liquid ring vacuum pump with air injector in order to improve the swept volume under lower suction pressure or more. Technology from abroad advanced enterprise on the technical data of it can be seen that single stage liquid ring vacuum pump with primary air injector, the suction pressure of 5 kPa, extraction rate can be up to the vacuum pump without air injection suction force of 400 hpa point extraction rate of the commonly used single stage liquid ring vacuum pump (user common condition point) of 65-70%, two levels of liquid ring vacuum pump with primary air injector, the suction pressure of 1.5 kPa point extraction rate can be up to the vacuum pump without air ejector suction pressure is 8 kPa point extraction rate (two-stage liquid ring vacuum pump commonly used point of 70-75%, In this way, the application scope of liquid ring vacuum pump is greatly expanded, which meets the requirements of chemical, pharmaceutical, light industry, instrument, metallurgy, power generation and other industries at the suction pressure of 1.5–5kPa point extraction rate process conditions. But at present domestic is a liquid ring vacuum pump with air ejector is not widely used;

Second, the pumping rate at 1.5-5kpa is relatively small, which has a certain gap with the technical level of foreign advanced manufacturers. For further popularization and application, should study to improve the atmosphere of injector design and the optimal formula of liquid ring vacuum pump, because the air in the atmosphere of injector nozzle (laval nozzle) and diffuser of tapered section of the flow is supersonic airflow, and the two strands of the airflow mixed with is pumped gases in the atmosphere in the process of momentum exchange is relatively complex, cannot completely depend on the theoretical calculation method to carry on the design, must test many times, but from the expansion of the application of liquid ring vacuum pump and improve the efficiency of perspective should strengthen the experimental research, efforts to improve the efficiency of extraction.