Material transport blower

Material conveying blowers of details

The special blowers for material conveying equipment has high control stability, easy operation, complete style, strong insulation, easy installation, high reliability, high compression ratio, low bearing operating temperature, no oil pollution, easy maintenance, beautiful appearance, Zui high quality, high pressure and high suction are generated by the unique design of impeller.

Material conveying blowers of performance

(1) The utility model has the functions of blowing and sucking, and can be used for both suction and blowing.

(2) Running with or without oil, the output air is clean;

(3) The feeding blowers is divided into pneumatic conveying and pipeline conveying.

(4) The shell is die-cast as a whole, and the shockproof mounting pedestal is used, so its requirement for the mounting foundation is very low. It can even run normally without fixing the pedestal, which is very convenient and saves installation cost and installation cycle.

(5) Wind blades with centrifugal force are made of inclined multi-blades in front of both sides. The mould is formed once. The computer has high quality dynamic balance. The vibration is very low, the wind is stable, the noise is low, and it can withstand certain frictional impact force, and the service life is long.

(6) The drainage side plate with built-in side suction nozzle, combined with the wind blade, can produce a large negative pressure suction force, making the self-suction feeding more stable.

The suction and feeding of suction blowers is based on material characteristics (granularity, bulk density, temperature, humidity, etc.), conveying distance, conveying capacity, site environment, cost budget and other factors to select the suitable power of Zui conveying blowers.

Material conveying blowers principle

1. Material suction system: Material suction blowers is mainly controlled by micro-computer system, abbreviated as material suction machine. When there is a lack of material in the barrel of material suction machine, it will give the signal of material suction machine. The suction machine uses the principle of suction blowers to convey the plastic material to the barrel of the injection machine. When the material reaches a certain level, the suction opportunity stops, and then it can be conveyed again when the material is insufficient.

2. Suction blowers: When the impeller of suction blowers rotates, due to the centrifugal force, the wind vane causes the gas to move forward and outward, thus forming a series of spiral movements. The air between blades of impeller rotates spirally and squeezes the plastic material outside the pump body into the designated barrel (inhaled by the suction port).

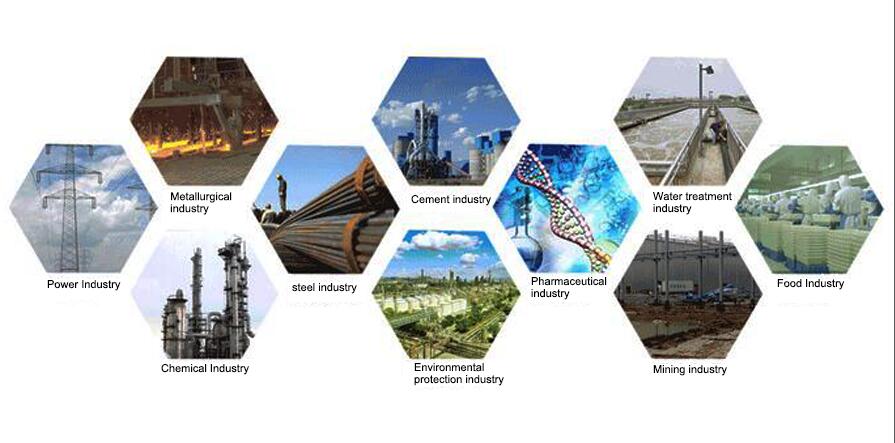

Application

Material Conveying Blowers of Performance Characteristics

The blowers is mainly used in wood processing enterprises such as wood-based panel factories, timber factories, furniture factories and other similar units. It can deliver wood or bamboo materials from place A to place B by means of wind power. Qingdao Material Transportation Induced Draft blowers has used foreign technology. Its characteristic is that the material such as big wood chips and bigger wood blocks can pass through the blower without obstruction, which overcomes the blocking and blocking fault when using other blowers in the same occasion. It has reasonable and firm structure, reliable and stable operation, high efficiency, strong adaptability to working conditions, low noise and convenient maintenance. It is an indispensable special equipment for wood, bamboo ware, furniture, plywood factory, compression board factory and other units.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)