Oil Diffusion Vacuum Pump Introduction and types

The diffusion pump uses a high-speed steam direct jet pump at the bottom of the throat gas molecules decomposed into the pump exhaust. Hosted in 1915 by Wolfgang Gade and using mercury vapor, they are high vacuum free molecular streams that move gas molecules better than the traditional hydrodynamic diffusion understanding of regime operation pump type I. GAD uses the name diffusion pump design because he finds that the gas cannot diffuse on the basis of the steam flow, but will carry with it the exhaust gas. However, the working principle may more accurately describe the jet pump, because diffusion plays an important role in other high vacuum pumps. In modern textbooks, diffusion pumps are classified as momentum transfer pumps. Diffusion pump is widely used in industry and research. Most modern diffusion pumps use as the working medium.

The oil diffusion pump operates as a low vapor pressure oil. Its aim is to achieve a higher vacuum (low pressure) by positive displacement pump only than using it is possible. Although its use is primarily related to high vacuum ranges (down to 10-9 mbar), today’s diffusion pumps produce pressures close to 10-10 mbar when appropriate with modern fluids and accessories. What makes the diffusion pump high and ultra-high vacuum attractive is that its high pumping all gases and pumping speed per unit cost is low, and the speed is used in the same vacuum range compared with other types of pumps. The diffusion pump cannot be discharged directly into the atmosphere, so the front mechanical pump is usually used to maintain the outlet pressure of about 0.1 mbar.

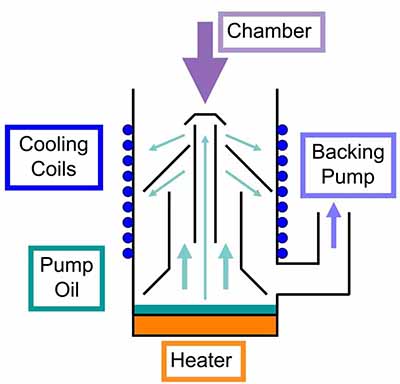

oil diffusion pump working principle diagram

High speed jet produces boiling liquid and directs assembly through jet steam. The nozzle changes from laminar flow to supersonic and molecular flow. Conventional fighters are used to enhance pumping operations. The diffusion pump adopts external cooling or air flow or water line. Due to the effect of steam jet cooling outside the diffusion pump casing, the working fluid is concentrated, recycled and directed back to the boiler. The pressure of pumping gas continues to flow into the foundation of the pump and where the outlet of the diffusion pump compresses the auxiliary front mechanical pump and the exhausted ambient pressure.

With turbo molecular pump and cryopump, diffusion pump has no moving parts, so it is quite durable and reliable. They can act in the pressure range of 10-10-10-2 mbar. They can only drive convection, which is very inefficient for energy.

One of the main disadvantages of diffusion pumps is the tendency to enter the vacuum chamber. This oil can contaminate the surface or interior of the back chamber in contact with hot wire or discharge and may cause deposits of carbon and silicon. Due to reflux, the oil diffusion pump is not suitable for use in highly sensitive analytical equipment or other applications requiring a very clean vacuum environment, but the mercury diffusion pump may be deposited with mercury in a super case of high vacuum chamber. Usually cold traps and baffles are used to minimize backflow, although in some cases pumping capacity is lost as a result.

A common mistake in the operation of an oil diffusion pump is in the atmosphere of hot oil contact. If this happens, the oil will burn and be replaced. A system shall always be cooled to the atmosphere before contact at room temperature.

Steam ejector is a kind of diffusion vacuum distillation and freeze pump popular drying. A steam jet pump considers that it must be removed from the steam vacuum chamber. Steam ejector can have one or more stages, with the no stages between condenser inches.

Compressed air injection pump

Among them, diffusion vacuum pumps are multistage compression driven jet air. This is a very popular application where the objects used are all over the place and the vacuum suction line moves out.