Selection of Vacuum Pumps in the PVD Industry

PVD (Physical Vapor Deposition) is a technology that, in a vacuum environment, vaporizes solid materials through physical methods (such as evaporation, sputtering, ion plating, etc.) and deposits them on the surface of a substrate to form a thin film.

1.Principles

Material Vaporization: Solid targets (e.g., metals, alloys, ceramics) are converted into gaseous atoms/molecules via heating (evaporation) or high-energy particle bombardment (sputtering).

Vapor Phase Transport: Gaseous particles move in a vacuum environment and reach the substrate (e.g., silicon wafers, glass, cutting tools).

Thin Film Deposition: Particles condense on the substrate surface to form a dense and uniform thin film.

2.Main PVD Technologies

| Technology | Principle | Characteristics | Application Examples |

| Vacuum Evaporation | Heating the target to vaporize it (via resistance heating or electron beam) | Thin films have high purity but generally moderate adhesion | Optical coatings (AR coatings), aluminum electrodes |

| Magnetron Sputtering | Bombarding the target with plasma to sputter atoms | High deposition rate, uniform thin films, suitable for large areas | Semiconductor metallization, ITO coatings for touchscreens |

| Arc Ion Plating | Vaporizing the target via arc discharge, followed by deposition after ionization | Thin films are dense and have strong adhesion, but may contain droplets | Tool coatings (TiN, DLC) |

| Ion Beam Deposition | Directly bombarding the target with ion beams and depositing | High-precision control, but complex equipment and high cost | Ultra-thin nanofilms, quantum devices |

3.PVD vs. CVD (Chemical Vapor Deposition)

| Item | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

| Principle | Physical process (no chemical reaction) | Chemical reaction (decomposition/reaction of gaseous precursors) |

| Temperature | Usually lower (room temperature ~ 500°C) | Higher (500°C ~ 1200°C) |

| Thin Film Properties | Dense, high purity, but poor step coverage | Good step coverage, but may contain impurities |

| Typical Applications | Metal films, hard coatings, optical films | Semiconductor dielectric layers (SiO₂, SiN), graphene |

4.PVD Application Industries

4.1. Semiconductor: Copper interconnections, aluminum electrodes (via magnetron sputtering).

4.2. Tool Coating: Depositing TiN and TiAlN on cutting tools and molds (to improve wear resistance).

4.3. Optical Coating: Anti-reflective (AR) coatings, mirrors (via vacuum evaporation).

4.4. Display Panels: ITO transparent conductive films (for touchscreens).

4.5.New Energy: Back electrodes of photovoltaic cells, thin films for solid-state batteries.

5.Advantages

5.1 Low-Temperature Process: Avoids high-temperature damage to substrates (e.g., plastics, precision parts).

5.2 Environmental Friendliness: No wet chemical processes, resulting in low pollution.

5.3 Diverse Materials: Capable of depositing metals, ceramics, and compounds.

PVD is a core technology for surface modification and functional thin film preparation in modern industry. It is widely used in high-tech fields and daily products (such as coatings for mobile phone screens, automotive headlights, and aircraft parts).

6.The selection of vacuum pumps

In the PVD (Physical Vapor Deposition) industry, the selection of vacuum pumps directly affects coating quality, process stability, and production efficiency. Different PVD technologies (e.g., magnetron sputtering, evaporation coating, ion plating) have different requirements for vacuum levels, so vacuum pumps need to be selected in a targeted manner. The following are recommendations for vacuum pump selection in the PVD industry:

6.1 PVD Process Stages and Corresponding Vacuum Requirements:

| Process Stage | Pressure Range | Core Requirements |

| Rough Pumping (Foreline Vacuum) | 1000Pa ~ 1 Pa | Rapidly pump to medium vacuum to reduce particulate contamination |

| High Vacuum Stage | 1 Pa ~ 10^-4 Pa | Stable pumping speed and prevention of oil contamination |

| Ultra-High Vacuum (for Some Processes) | <10^-4Pa | Ultimate vacuum and no hydrocarbon contamination |

6.2 Common Vacuum Pumps in the PVD Industry and Their Advantages & Disadvantages Comparison

6.2.1 Rough Pumping Stage (Foreline Pump)

Its main task is to quickly pump the chamber from atmospheric pressure to medium vacuum (approximately 1 Pa).

| Pump Types | Rotary Vane Pump/Rotary Piston Pump (Oil-lubricated Vacuum Pump) | Dry Screw Pump / Claw Pump / Scroll Dry Pump (Oil-free Pump) |

| Advantages | Low cost and stable pumping speed. | No oil contamination, suitable for high-cleanliness PVD (e.g., optical coating, semiconductor). |

| Disadvantages | Possible oil backflow, which contaminates the chamber (not suitable for high-cleanliness PVD). | Higher price and slightly higher maintenance cost. |

| Applicable Processes | Ordinary magnetron sputtering, evaporation coating (non-high-purity applications). | High-end PVD, CIGS photovoltaic coating, OLED coating. |

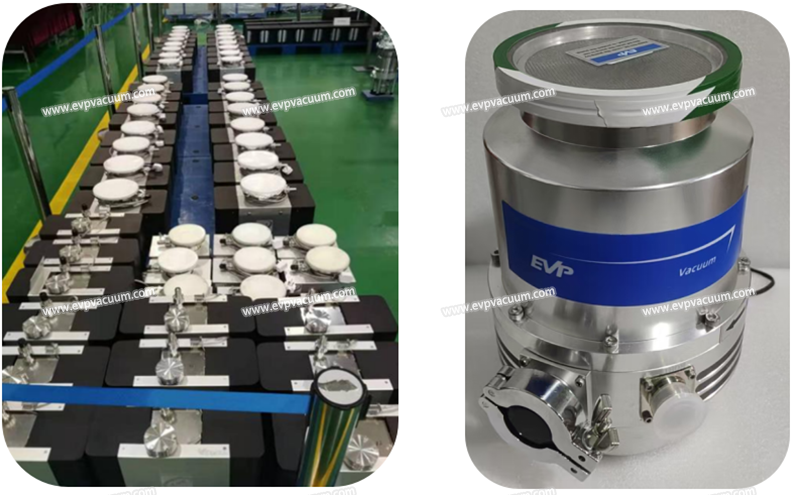

6.2.2 High Vacuum Stage (Main Pump)

Its main task is to increase the vacuum level to 10^-3Pa ~ 10^-6Pa and maintain a stable coating environment.

| Pump Types | Turbomolecular Pump | Cryopump | Oil Diffusion Pump |

| Advantages | High pumping speed (100~5000 L/s) and no oil contamination (magnetic levitation type is better). | Extremely high pumping speed (especially for water vapor and Ar gas) and no oil contamination. | Low cost and high pumping speed (commonly used in traditional PVD). |

| Disadvantages | Low pumping speed for light gases (H₂, He), requiring matching with a foreline pump. | Regular “regeneration” (heating for gas exhaust) is needed, and it cannot work continuously. | Possible oil backflow, which contaminates the film (gradually replaced by turbomolecular pumps). |

| Applicable Processes | Magnetron sputtering, electron beam evaporation, semiconductor coating. | High-flow reactive sputtering (e.g., Al₂O₃, TiO₂ coating) | Low-end PVD equipment (e.g., tool coating). |

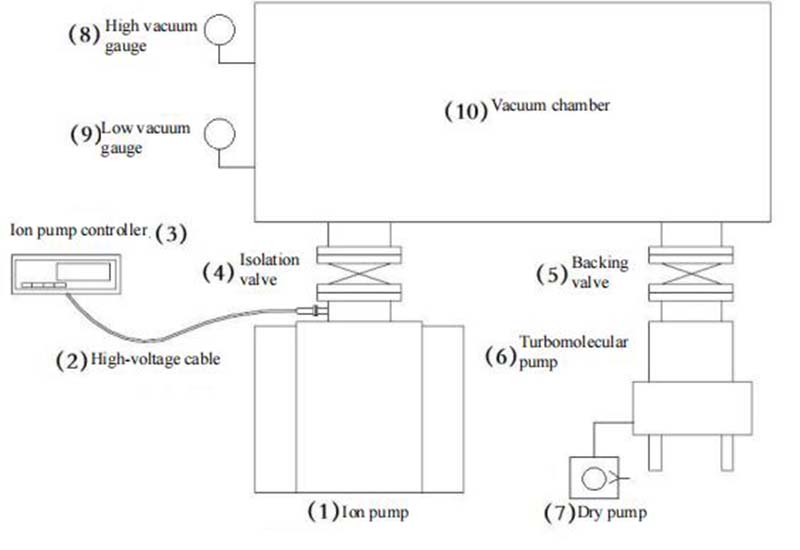

6.2.3 Ultra-High Vacuum Stage (Sustaining Pump)

Its main task is to maintain an ultra-high vacuum of <10^-6Pa (e.g., MBE – Molecular Beam Epitaxy).

| Pump Types | Ion Pump | Titanium Sublimation Pump (TSP) |

| Advantages | Oil-free, vibration-free, with an ultimate vacuum up to 10⁻¹¹Pa. | High pumping speed for active gases (O₂, N₂) and oil-free. |

| Disadvantages | Low pumping speed, not suitable for high gas load. | Needs to be used with an ion pump. |

| Applicable Processes | MBE, ultra-high vacuum coating, scientific research-grade PVD. | High-purity semiconductor coating. |

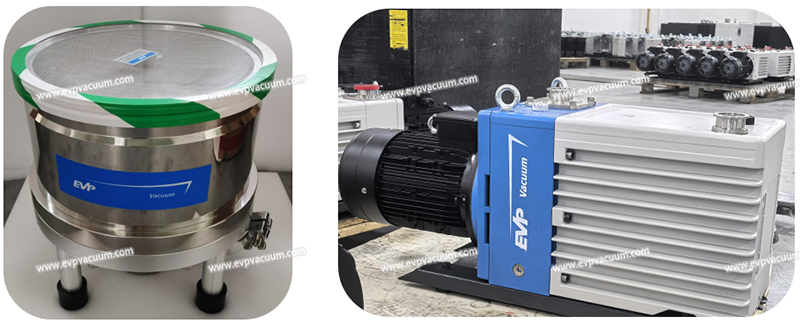

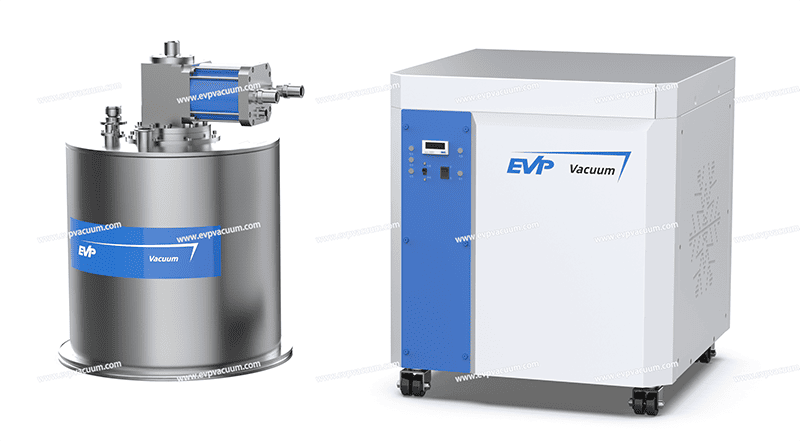

6.3 EVP Vacuum Pump Selection Recommendations for Different Processes in the PVD Industry

6.3.1 For the electron beam evaporation process, we recommend the cost-effective oil-sealed rotary vane pump and turbomolecular pump unit, which is suitable for metal evaporation.

6.3.2 For the mass-production magnetron sputtering process, which has high cleanliness requirements, we recommend a pump unit combining a dry pump and a turbomolecular pump.

6.3.3 For the reactive sputtering (Al₂O₃) process, we recommend a combination of a dry vacuum pump, Turbomolecular pump, and Cryopump. After reaching the target vacuum, the turbomolecular pump and dry pump can be stopped, which can efficiently pump out O₂ and H₂O and avoid contamination.

6.3.4 The MBE (Molecular Beam Epitaxy) process requires ultra-high vacuum. We recommend a turbomolecular pump matched with a dry pump unit, combined with an Ion pump and assisted by a titanium sublimation pump, to meet the requirement of ultimate vacuum and realize a hydrocarbon-free contamination process.

6.3.5 During the optical coating process, dust is usually generated. We recommend a combination of a purgeable magnetic levitation turbomolecular pump and a dry screw pump or scroll dry pump to achieve ultra-high cleanliness and prevent the process products from being contaminated by oil vapor.

For more information on applications of vacuum pump in the PVD or CVD industry, please consult the EVP Vacuum Team.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)