This article will introduce you to several vacuum pumps used in ultra-high vacuum and ultra-high vacuum fields!

When the pressure exceeds 10-5Pa, it enters the field of ultra-high vacuum application. At this time, the vacuum pumping of most vacuum pumps has stopped or the pumping speed is very low. What are the vacuum pumps used to achieve ultra-high vacuum at this time? Let’s take a brief look.

Mechanical pump

The main function of the mechanical pump is to provide the necessary fore vacuum for the start-up of the turbomolecular pump. Commonly used mechanical pumps include vortex dry pumps, diaphragm pumps and oil-sealed mechanical pumps.

Diaphragm pumps have a lower pumping speed but are small in size and are generally used in small molecular pump groups.

Oil-sealed mechanical pumps were the most commonly used mechanical pumps in the past. They are characterized by high pumping speed and good ultimate vacuum. Their disadvantage is that oil return is common. When used in ultra-high vacuum systems, they generally need to be equipped with solenoid valves (to prevent oil return caused by accidental power failure) and molecular sieves (adsorption effect).

In recent years, the vortex dry pump has been widely used. Its advantages are that it is relatively simple to use and will not return oil, but its pumping speed and ultimate vacuum are slightly worse than those of oil-sealed mechanical pumps.

Mechanical pumps are an important source of noise and vibration in the laboratory. It is a good idea to choose low-noise pumps and place them in the equipment room as much as possible. However, due to working distance limitations, the latter is usually not easy to achieve.

Turbomolecular pump

Turbomolecular pumps rely on high-speed rotating blades (usually around 1000 revolutions per minute) to achieve directional flow of gas. The ratio of the exhaust pressure of the pump to the intake pressure is called the compression ratio. The compression ratio is related to the number of pump stages, rotation speed and type of gas. Generally, gases with large molecular weight have higher compression ratios. The compression ratio for nitrogen is 108-109; for hydrogen it is 102-104. The ultimate vacuum of a turbomolecular pump is generally considered to be 10-9-10-10mbar. In recent years, with the continuous advancement of molecular pump technology, the ultimate vacuum has been further improved.

Since the advantages of turbomolecular pumps can only be realized in the molecular flow state (the flow state in which the mean free path of gas molecules is much larger than the maximum size of the conduit cross section), it is required to be equipped with a fore-stage vacuum pump with a working pressure of 1 to 10-2Pa. Due to the high-speed rotation of the blades, if foreign matter, shaking, impact, resonance or gas shock is encountered, the molecular pump will be damaged or damaged. For beginners, the most common cause of damage is gas shock caused by operating errors. Resonance caused by mechanical pumps can also cause damage to molecular pumps. Although this situation is relatively rare, it is more hidden and difficult to find, so special attention should be paid.

Sputtering ion pump

The working principle of the sputtering ion pump is to use the ions generated by Penning discharge to bombard the titanium plate of the cathode to form a fresh titanium film, thereby adsorbing active gases and having a certain burying effect on inert gases.

The advantages of sputtering ion pumps are good ultimate vacuum, no vibration, no noise, no pollution, mature and stable technology, no maintenance, and at the same pumping speed (except for inert gases), its cost is much lower than that of molecular pumps, so it is widely used in ultra-high vacuum systems. Usually the normal working cycle of sputtering ion pumps is more than 10 years.

Ion pumps generally need to work properly above 10-7mbar (working under worse vacuum will significantly reduce their lifespan), so a molecular pump group is needed to provide them with a better fore-stage vacuum. A common practice is to use an ion pump + TSP in the main chamber, equip the injection chamber with a small molecular pump group, open the connected plug valve during baking, and the small molecular pump group provides fore-stage vacuum. After baking, close the plug valve, and the ion pump cooperates with the TSP to achieve ultra-high vacuum.

It should be noted that the ion pump has poor adsorption capacity for inert gases, and its maximum pumping speed is somewhat different from that of the molecular pump. Therefore, a molecular pump group is required for situations where the outgassing volume is large or there is a lot of inert gas. In addition, the ion pump will generate an electromagnetic field during operation, which may interfere with particularly sensitive systems

Cryogenic pump

Cryopumps mainly rely on low-temperature physical adsorption to obtain vacuum. The advantages are high pumping speed, no pollution, and high ultimate vacuum. The main factors affecting the pumping speed of cryopumps are temperature and the surface area of the pump. In large-scale molecular beam epitaxy systems, cryopumps are widely used due to the high requirements for ultimate vacuum. The disadvantages of cryopumps are large liquid nitrogen consumption and high operating costs. Systems with circulating refrigerators do not consume liquid nitrogen, but will bring corresponding energy consumption, vibration and noise problems. Therefore, cryopumps are rarely used in conventional laboratory equipment.

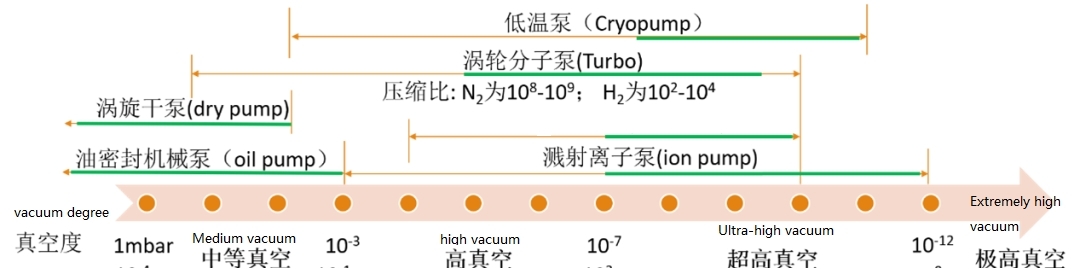

The working pressure corresponding to different types of pumps. The brown arrow range is the maximum allowable working pressure range, and the green bold part is the commonly used working pressure range.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)