Vacuum gauge in freeze drying process

In the process of freeze-drying monitoring, vacuum data should be believed. Do not trust product temperature data. Because the product temperature we read is always deceiving you.

The setting and control of vacuum value in primary drying process is the most important parameter in the whole process.

This article explains in detail: vacuum measurement – vacuum gauge

1. Pressure unit

Atmospheric pressure (Standard) =

14.7:pounds per square inch (psia)

29.9:inches of mercury

760:millimeter of mercury

760:torr

760,000:millitorr or microns

101,325:pascal, 1 pascal: 0,01 mbar: 10 µbar

1.013:bar

1,013:millibar, mbar

1,013,250:microbar, µbar

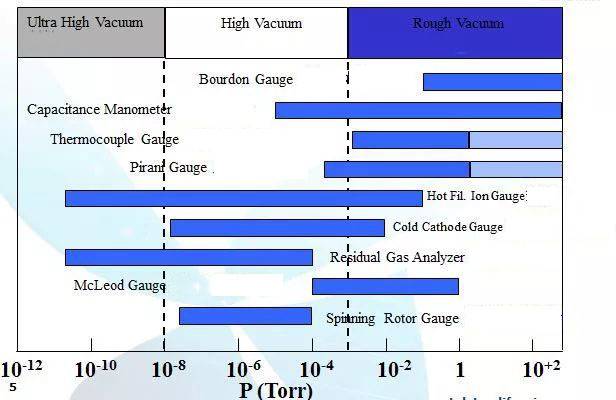

There are various types of vacuum meters, as follows:

Bourdon Gauge

Capacitance Manometer

Thermocouple Gauge

Pirani Gauge

Hot Filament Ionization Gauge

Cold Cathode Ionization Gauge

Residual Gas Analyzer

McLeod Gauge

Spinning Rotor Gauges

3. Measurement range of vacuum gauge

Different types of vacuum meters have different measuring ranges (ranges):

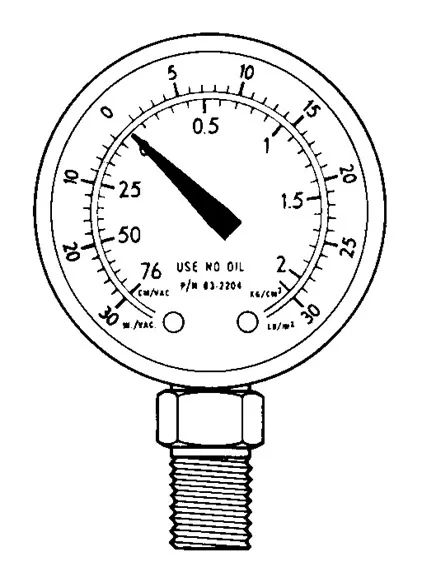

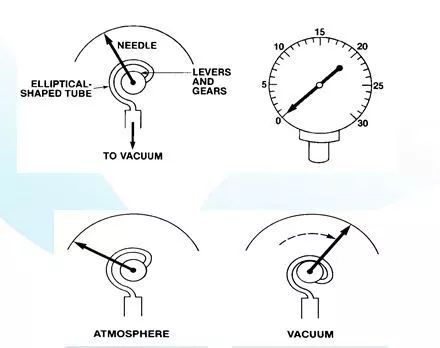

4.Bourdon gauge

Working principle: different gas pressure, different pointer position, different value indicated.

Burton pressure gauge, because it cannot be calibrated, cannot be used for freeze-drying process monitoring. It can only be used for the understanding of rough effect vacuum.

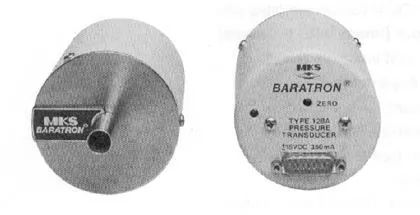

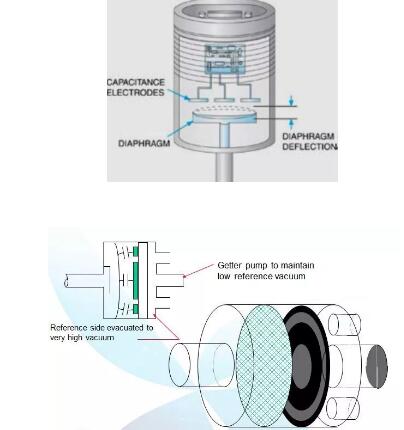

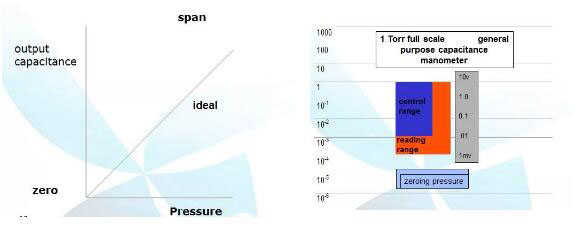

5.Capacitance gauge

Range: 4 decades (starting at 1000T to .1 Torr)

Response : Very Fast – <1 msec

Application: Process Pressure Control

Accuracy : +/- .25% Full Scale

Measure absolute vacuum value

The pressure value is linear with the output capacitance value

Principle: different vacuum degree means different film position. The output capacitance is different with different film position. The relationship between pressure and output capacitance is linear.

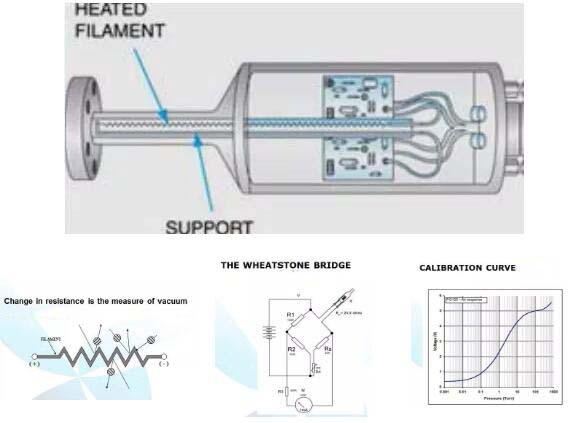

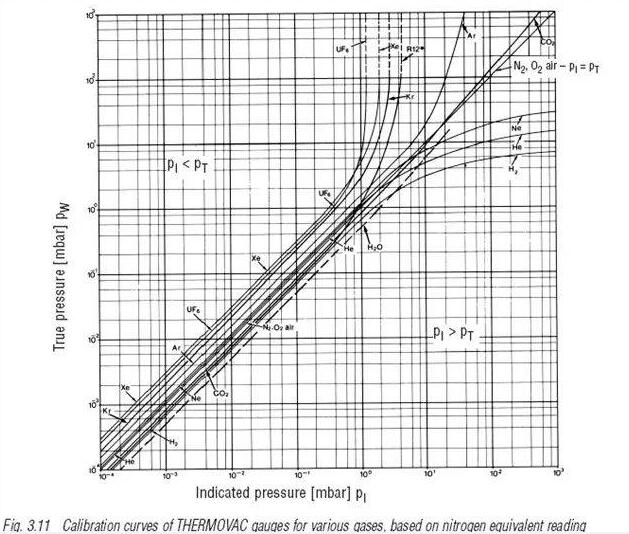

Principle: with different vacuum degrees, the number of air molecules per unit volume is different. The heat carrying capacity (heat dissipation capacity) of the heating resistance wire is different, and the temperature of the resistance wire is different. Because the resistivity of the resistance wire is a function of temperature, different vacuum degrees cause different resistivity, so the resistance is different, and the voltage drop of current on the resistance wire is different, According to the change of voltage, the air pressure can be converted, that is, the vacuum degree can be measured.

The calibration gas of Pirani vacuum gauge is nitrogen. When measuring nitrogen, Pirani vacuum gauge and capacitance vacuum gauge display the same value.

It should be noted that the thermal conductivity of water vapor is about 1.6 times that of nitrogen. So the same absolute vacuum, if it is water vapor, will be about 60% higher than nitrogen.

7. Primary drying and freeze-drying end point

Using the above characteristics, because the chamber pressure in the primary drying process is mainly from sublimated water vapor, if the drying chamber is equipped with a Pirani vacuum gauge and a capacitance vacuum gauge at the same time, the value of the Pirani vacuum gauge is always higher than that of the capacitance vacuum gauge. Until the end of freeze-drying, the gas composition changes from most of water vapor to most of nitrogen, and the two pressure gauges tend to be the same.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)