vacuum pump for degassing

Steam jet vacuum pump and roots vacuum pump have been used in the process of vacuum degassing for many years. There are great differences in design principle and function between the two kinds of vacuum pumps. Roots vacuum pump is a positive displacement pump, which can only pump clean gas and low temperature gas. Therefore, it must be installed with efficient dust removal equipment, such as centrifugal filter or bag filter. The steam jet pump is a quality pump, which can pump the gas without dedusting. The practice shows that pumping the gas without dust removal will lead to the accumulation of pollutants, reduce the pumping capacity and shorten the cleaning and maintenance period. The reason why the steam jet pump has a higher pumping capacity is that it has a higher scale capacity. Higher design capacity also enables the pump to achieve the required output capacity at the lowest pressure.

Vacuum pump type

When degassing the ladle and converter, the static VD process is used to degass the killed steel, the VCD process is used to deoxidize the carbon, and the VOD process is used to decarbonize the oxygen. There are two types of vacuum pumps used in the past 25 years, steam jet vacuum pump and roots vacuum pump. In smelting, operation, environment and economy, the combination of the two and water ring vacuum pump can achieve good results. However, the dry roots vacuum pump system still shows its outstanding advantages. There are great differences in design and function between the two kinds of vacuum pumps, because the particularity of degassing process is not fully considered.

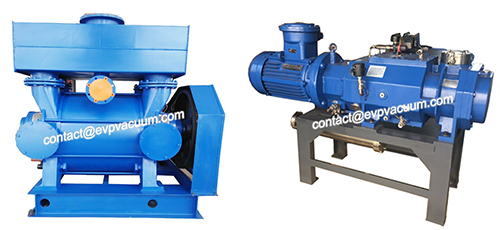

Roots vacuum pump

Roots vacuum pump is a positive displacement pump. It can only pump clean and dust-free low-temperature gas, which is composed of 4-6 stages. Water ring vacuum pump is usually used as high pressure stage. The number of stages is determined by the compression ratio of each vacuum pump to ensure that the efficiency and energy consumption of the vacuum pump are optimal. In the process of vacuum deoxidation, roots vacuum pump can meet the needs of large volume and high speed pumping or large mass flow. In the low pressure range of 30hpa-0.5hpa, the pumping capacity is constant for the volume flow and linear for the mass flow. The flow rate varies with the gas load. Roots vacuum pump system must be equipped with efficient dust removal equipment, and some stages need to be cooled in the middle by a cooler. For a vacuum system with a pressure of 10-0.2hpa and a pumping speed of m0000m3 / h (equivalent to a mass flow of 160kg / h under LHPA pressure), the multi-stage Roots vacuum pump can be used as a water ring vacuum pump with low operating cost. For the roots vacuum pump system with a total power of 600 kW, when it starts to extract air rapidly from atmospheric pressure, its peak power is less than 300 kW, and it drops to 100 kW in the process of vacuum degassing. The flow rate of pure water is 20m3 / h and the temperature rise is 10 ~ C. The water flow rate of water seal of water ring vacuum pump is 15m3 / h. The water seal water is in contact with the exhaust gas, which contains slight pollution. The exhaust gas contains residual pollution (less than 20mg / m3), sometimes a small amount of Co. Therefore, the total power of Roots vacuum pump, water ring vacuum pump and cooling fan is less than 1kwh / T for 60-120t ladle.

Steam jet pump

The steam jet pump is a mass pump, which uses the superheated steam as the driving gas. Through collision, the steam transmits the energy to the extracted gas molecules and dust particles to realize the extraction process. Lighter gases (such as H2) consume less energy than heavier gases (such as CO2, AR), while dust particles are equivalent to super molecules, which will absorb a lot of energy when they are removed. The steam jet pump system can be composed of 4-6 stages according to the compression ratio and the water temperature requirements of the intermediate condenser. The higher the water temperature, the more stages are required. The allowable water temperature range is below 35 ℃. The more stages, the less steam consumption. The high pressure stage is preferably composed of a water ring vacuum pump. According to the analysis of mass flow rate, the extraction capacity of steam jet pump is neither linear nor constant. Each stage has an optimal working pressure point, beyond which the mass flow increases slowly; below which the mass flow decreases rapidly. Therefore, the mass pumping capacity of the system needs to be configured to be nearly linear.

Because of thermodynamics, the low pressure stage of vacuum pump system can not be installed with an intermediate condenser, while the high pressure stage jet pump must have the ability to pump out steam at the low pressure stage. During operation, when the first low-pressure pump starts, there is a step of pumping capacity because the non working low-pressure vacuum pump has not supplied air to the first low-pressure pump. This phenomenon occurs in the critical pressure range below 70hpa. At this time, most of the metallurgical degassing reactions have just begun, especially in the treatment of semi killed steel and steel with oxidizing slag. In order to prevent the splashing or serious overflow of steel and steel slag from the ladle, the low-pressure pump must be equipped with an air ballast device which uses air, steam or exhaust gas to balance the pressure, so that the vacuum degree can be maintained stably when the gas is separated from the molten steel In a certain range. For 60-80t ladle, steam consumption is only 3-6t / h, fuel consumption is 200-4001 / h and cooling water consumption is 3-6m3 / h. The consumption of industrial water for steam condensation varies in the range of 150-600m3 / h due to different inlet water temperature.

The condensed water is seriously polluted in the stage of VOD, mixed with dust and Co. The condensate can be recycled through the vacuum pump system circuit, but the collecting tank and hot well must be ventilated by fans or the harmful CO gas in the water must be removed. The sump must also be equipped with a mud pump. The total power of water ring vacuum pump, circulating pump, fan and mud pump is more than 350kW, about 250KW is consumed constantly. The consumption does not fully reflect the operating cost of the steam jet pump. When the steam jet pump is used to deal with the gas without dedusting, it will lead to the deposition of pollutants in the low pressure stage pump, reduce the working gap in some specific areas, reduce the pumping capacity of the pump, and eventually reduce the vacuum degree. During regular repair, the pump body must always be cleaned with a high-pressure water gun (> 500bar).

As the sludge contains many heavy metals, it must be transported to a special place for disposal. In order to reduce dust pollution and prolong the cleaning period, the steam jet pump system is more and more equipped with dust collection equipment such as centrifugal dust collector. The dust collector can filter out the large particle dust and about 50% dust in the gas, but it will not cause excessive pressure loss. Although local dust collection is adopted, the steam jet pump should be designed to ensure that when the throat of the low-pressure vacuum pump is partially blocked, the pumping capacity of the pump can still reach the required load.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)