Vacuum Pumps in Direct Air Capture (DAC) Systems of Application

Working Principles and Operational Mechanisms of Vacuum Pumps in DAC Systems

Adsorption Phase: Ambient air is drawn into the DAC unit by large fans, passing through a CO₂-selective sorbent (e.g. amine-impregnated filters or solid sorbent beds). CO₂ is captured from the air at ambient pressure while other gases pass through.

Desorption Phase: Once the sorbent is saturated with CO₂, the capture chamber is isolated and regeneration begins. The sorbent is typically heated (often to 80–100 °C) to release the bound CO₂. Simultaneously, a vacuum pump evacuates the regeneration vessel. By lowering the pressure above the sorbent, the vacuum pump reduces the partial pressure of CO₂, causing the CO₂ molecules to desorb and enter the gas phase. This is analogous to “squeezing” the CO₂ out of the sorbent – just as heat + vacuum causes a sponge to release water.

Vacuum-Assisted CO₂ Release: The vacuum pump’s role is critical: by maintaining a low pressure in the regeneration chamber, it enables efficient CO₂ release. As Busch Vacuum explains, “vacuum is essential” to desorption – reducing pressure in the collector allows captured CO₂ to detach from the filter and return to the gas state. CO₂ Collection: Once released, the nearly pure CO₂ gas is drawn out by the vacuum pump for downstream processing (compression, purification, storage or utilization). The pump typically delivers the CO₂ to compressors or separation stages. In practice, multiple pump units are operated in parallel or stages to handle the large air flows and achieve the required low pressures. Overall, vacuum pumps in DAC systems create and maintain the low-pressure environment needed for sorbent regeneration, directly enabling the capture cycle

Comparison of Common Vacuum Pump Types Used in DAC

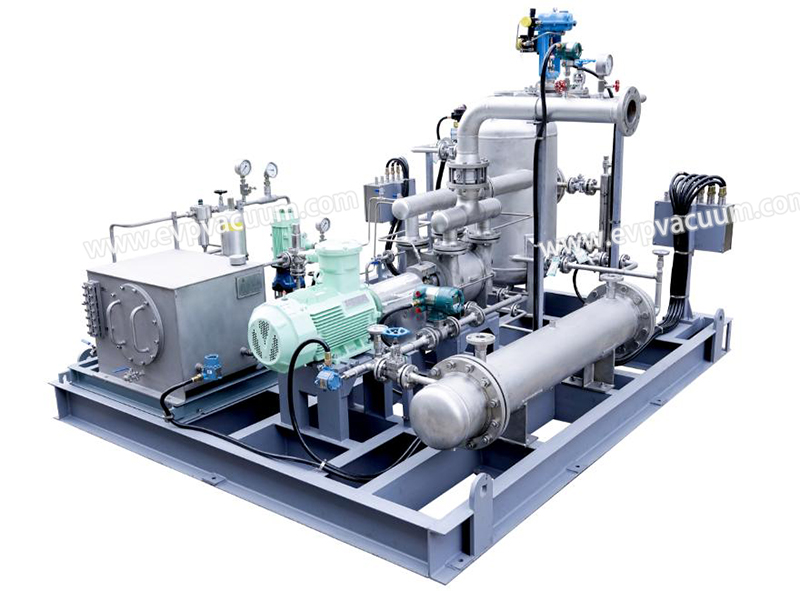

Vacuum pumps for DAC must handle large volumetric flows (atmospheric air) and often wet, CO₂-rich gas. The most commonly used types include dry screw pumps, dry claw (Roots-type) pumps, liquid-ring pumps, and turbomolecular pumps. Key attributes of each are:

Dry Screw Vacuum Pumps: These positive-displacement pumps use two intermeshing screws to compress gas. Dry screw pumps are oil-free (no oil in the pumped gas) and can handle moderate moisture. They are highly efficient and can reach rough to medium vacuum levels (~mbar range). In DAC applications, dry screw pumps are often paired with liquid-ring or mechanical booster pumps to achieve deeper vacuum without contamination. For example, some vacuum pump manufacturer notes that its dry screw pumps (with attached boosters) can evacuate CO₂ “without seal liquid contamination,” making them well suited to solvent-based CO₂ capture. Dry screws typically require periodic maintenance (e.g. oil for lubrication, filter changes) but deliver high throughput and are compatible with amine solvents and CO₂. Variable-speed (VSD) drive versions enhance their energy efficiency

Dry Claw/Roots Pumps: Claw pumps (a type of dry Roots blower) use two claw-shaped lobes (rotors) that mesh without contact. They are 100% oil-free and extremely reliable, providing a uniform vacuum. Dry claw pumps are robust against humid or dirty gases and achieve vacuum down to a few millibars (often two or more stages in cascade). Claw pumps are widely used in DAC. Their simplicity and lack of lubrication make them low-maintenance and well-matched to the water vapor in flue air or ambient air.

Liquid-Ring Vacuum Pumps: These pumps use a rotating liquid (usually water or oil) to create seals that compress gas. Liquid-ring pumps are inherently wet pumps, making them excellent at handling condensable vapors and fine particles. They typically achieve vacuum down to about 5–10 mbar (depending on liquid temperature). Liquid-ring pumps operate isothermally (heat is carried away by the liquid) and can tolerate harsh gas mixtures (e.g. amine solvents, acidic or toxic gases) with corrosion-resistant liquid options. The trade-offs are lower efficiency and higher power consumption compared to dry pumps. However, manufacturers emphasize their reliability and simple maintenance. Additionally, liquid-ring pumps have the unique advantage of allowing large amounts of water vapor in the inlet gas – “a large amount of water vapor and small solids,” which they handle more easily than dry pumps. This makes them attractive for DAC processes operating at scale.

Turbomolecular (High-Vacuum) Pumps: Turbo pumps consist of fast-spinning blades that impart momentum to gas molecules, achieving extremely high vacuum (down to 10^−6 mbar or better). They are oil-free and suitable for ultra-clean systems, but have very low throughput and require backing pumps. Turbopumps do not handle moisture or large gas volumes, so they are generally not used for industrial-scale DAC. Instead, they may appear in lab-scale or pilot DAC setups where very deep vacuum is needed on a small sample. In practice, DAC applications stick to rough/medium vacuum pumps (screw, claw, liquid-ring) for the bulk of CO₂ desorption. Turbo pumps might be used in peripheral roles (e.g. evacuating instrumentation), but not for the main DAC vacuum duty.

Each pump type has trade-offs in energy use, footprint, and operating conditions. In summary, dry screw and claw pumps offer oil-free operation and higher efficiency, suitable for clean-medium vacuums, whereas liquid-ring pumps excel at wet, heavy-duty service with simple maintenance. Atlas Copco and Busch both note that dry screw, claw, and liquid-ring pumps are all viable choices for DAC, with the final selection depending on humidity, required vacuum, and scale.

Real-World DAC Projects and Vacuum Pump Deployment

At present, global DAC projects are being rapidly deployed, and vacuum pumps, as core equipment, are widely adopted. A factory built by a certain company in Iceland uses claw dry pumps from European and American manufacturers to vacuum regenerate solid adsorbents and inject the captured CO₂ into basalt formations for storage. The technology of a certain enterprise in the United States is based on porous solid adsorbents and uses low-temperature vacuum adsorption/desorption cycles to capture CO₂ in the air. Many vacuum pump manufacturers have also reported that their dry pumps and pressurization systems have been verified in North American DAC installations and can support demands ranging from pilot to large-scale. A major vacuum equipment supplier, they offer a series of products including screw pumps, liquid ring pumps, oil-free claw pumps, etc., for different DAC process routes. Overall, DAC projects typically select a combination of dry pumps or liquid ring pumps that are resistant to water and dust and have high energy efficiency to meet the requirements of long-term operation and automation

Energy Consumption, Operational Cost, and Maintenance Requirements

Energy Consumption: Vacuum pumps can be significant power consumers in a DAC system. Continuous pumping of large gas volumes against low pressure requires substantial electricity. To mitigate this, modern pumps often use Variable Speed Drives (VSDs) or on-demand control. Some manufacturer notes that their vacuum pumps allow customers to “increase their energy efficiency and reduce CO₂ emissions”, since pump speed (and power draw) can adapt to load. In practice, power use varies by pump type: dry pumps (screw, claw) typically consume less power than liquid-ring pumps for the same suction capacity because they have higher isentropic efficiency. As one source notes, a screw pump can be 10–20% more energy-efficient than a comparable liquid-ring unit. However, liquid-ring pumps may be more energy-efficient when pumping saturated air (since they condense latent heat internally). Overall, vacuum pumping may account for a nontrivial portion of a DAC plant’s electricity use. Manufacturers emphasize efficiency

Cost of Operation: Operational costs include the electricity above plus consumables like pump oil and seal liquid. Dry pumps (screw, claw) use minimal consumables, whereas liquid-ring pumps continuously consume the working fluid (usually water with corrosion inhibitors). The capital cost of dry pumps is generally higher: one vacuum-industry source estimates that a screw vacuum pump costs about 30% more than a liquid-ring pump for the same capacity. However, dry pumps can save money by eliminating seal fluid purchases and by lowering compression work. Besides energy, operators pay for periodic maintenance: oil changes, filter replacements, etc.

Maintenance Requirements: Reliability and maintenance vary by pump type. Dry screw and claw pumps have tight tolerances and may require scheduled maintenance. For example, some screw pumps mandate service every ~8,000 operating hours (changing lubricant, filters, etc.). In contrast, liquid-ring pumps have very few wear parts and can often run for 2–3 years without major repairs. Some manufacturers promote their pumps as low-maintenance; for instance, some highlights that its pumps needs “minimal maintenance” even in continuous duty, and some emphasizes “exceptional reliability and low maintenance” in its carbon capture pumps. In practice, maintenance planning (e.g. redundancy and spare parts) is critical for DAC plants, since an offline vacuum pump can halt CO₂ production. Predictive maintenance (via sensors, remote monitoring) is also a growing focus. Manufacturers now offer integrated diagnostics to minimize downtime.

In summary, vacuum pumps represent a significant share of DAC operating cost through electricity and upkeep. Dry pumps typically yield lower running costs (higher efficiency, no seal fluids) at the expense of higher upfront price, while liquid-ring pumps trade slightly higher energy use for extreme robustness. Optimizing pump operation with VSDs, staging, and water-cooling (for screw pumps handling humid air) helps reduce energy bills. Regular maintenance intervals must be built into plant schedules. According to industry sources, a well-designed DAC vacuum system can run sustainably with managed energy demand and planned service, contributing to the overall “low maintenance” operation touted by suppliers.

Latest Research, Technological Developments, and Future Trends

With the development of DAC technology, desorption methods and vacuum pump technology have been constantly innovated. Some studies have proposed steam/water vapor desorption promotion strategies, which significantly reduce the system’s reliance on deep vacuum and high temperatures by introducing water vapor heat transfer or water decomposition. For instance, in 2024, an in-situ water vapor-assisted desorption method was reported: at approximately 100 ° C, concentrated water vapor was used to promote the desorption of CO₂, and the prototype achieved a CO₂ purity of 97.7% and simultaneous water production without a vacuum pump or steam boiler. This “steam-promoted desorption” not only enhances the CO₂ desorption efficiency but also reduces the overall energy consumption by 20%, significantly improving the economic efficiency of the DAC. In addition, catalytic and membrane-combined regeneration technologies, low-temperature waste heat-driven processes, etc. are also under exploration.

At the equipment level, vacuum pump manufacturers continue to introduce more efficient and intelligent products. Some companies adopt technologies such as variable frequency speed control and magnetic levitation turbine bearings to enhance the efficiency and extend the lifespan of vacuum pumps, and support a cyclic operation mode. In terms of system integration, existing solutions couple vacuum pumps with modules such as blowers and condensers to further save energy and accelerate the regeneration process through waste heat recovery and water vapor condensation. Looking ahead, with the development of new adsorption materials (such as MOF, superhydrophobic modified adsorbents, etc.) and the application of digital control and predictive operation and maintenance technologies, the energy efficiency and reliability of DAC vacuum systems will continue to improve, making DAC a more economical and sustainable negative carbon technology.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)