Water ring vacuum pump in pulp bleaching

The paper industry is one of the ten pillar industries of the national economy in developed countries. At present, the development of China’s paper industry has entered a period of rapid growth, and the paper industry has become a hot industry in China’s economic development. Papermaking industry is a light industry with large output, much water and serious pollution. Water pollution ranks first among all kinds of industries. Pollution of waste gas, solid waste and noise is also very serious.

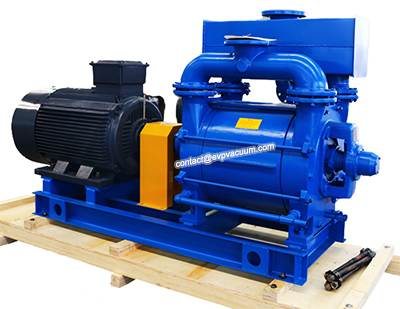

In recent years, we have provided reliable vacuum pumps and water ring vacuum pumps for pulp bleaching. Through product upgrading, we will continue to provide more innovative solutions, further improve reliability, and improve customers’ energy saving and profitability. The practical application of water ring vacuum pump in pulp bleaching has proved that it can help the pulp and paper industry to produce high quality paper at lower cost. As for why we choose water ring vacuum pump, let’s find out.

water ring vacuum pump in pulp bleaching

Principle of ozone oxidation technology: the main components of odor waste gas are ammonia, hydrogen sulfide, mercaptan, thioether, phenol, amine, amide, indole, alkane, alkene, alkyne, aromatic hydrocarbon, alcohol, aldehyde, ketone, organic acids (VOC) and inorganic substances, of which the amount of ammonia is the largest, followed by hydrogen sulfide (the contribution rate of hydrogen sulfide to odor is the largest). These components are the key points in the design Part of the consideration. The absorption characteristics of acid absorption, alkali absorption and neutral absorption are studied comprehensively. According to the above characteristics of waste gas compounds, the chemical absorption method of ozone oxidation technology is used as the pretreatment process of waste gas treatment. Ozone is a strong neutral chemical absorption oxidant, and it has no secondary pollution, and after oxidation reduction to oxygen (O2) and water (H2O) decomposition gas, it has low volatility and cracking Odor gas makes the free pollutant molecules combine with ozone oxidation to form small harmless or low harmful compounds, such as CO2, H2O, etc.

The use of ozone as an oxidant to bleach paper pulp has developed into an environmentally friendly alternative to the traditional use of chlorine. Ozone is ideal for this process because it is an unstable gas that quickly changes to oxygen after bleaching, leaving a clean pulp free of harmful chemicals. It also reduces air and water pollution.

In this application, our water ring vacuum pump is used to compress ozone gas to mix with pulp. The vacuum pump has the characteristics of isothermal compression, which will not lead to the thermal degradation of temperature sensitive ozone gas.

The specific application of water ring vacuum pump in pulp bleaching, conclusion: the process flow is short, the operation is stable, the cost is low, the compressed ozone gas can reach the required pressure and concentration, and the equipment is simple, the operation is stable and not easy to fail. The ozone gas with high concentration and pressure can be used in environmental engineering, circuit cleaning, fabric bleaching, medical and other industrial fields.

According to the new achievements of international bleaching technology in environmental protection and the development direction of domestic papermaking environmental protection policies, it is the general trend to implement stricter discharge standards for papermaking wastewater. At the same time, the cost of traditional bleaching process increases with the increase of chemical product price. Therefore, the use of cheap oxygen to further remove the lignin in the pulp can save chemicals, reduce the pollution load of waste water, and promote the simultaneous improvement of the three benefits of the enterprise.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)