Water ring vacuum pump of condenser principle and operation

The traditional equipment of condenser vacuum pumping mainly adopts steam ejector and water ejector, but both of them have the disadvantages of low efficiency and high noise. With the development of steam turbine to high parameter and large capacity, it is uneconomical to use this kind of equipment. If the water ring vacuum pump is used, the efficiency can be greatly improved and the energy consumption and noise pollution can be reduced. This kind of water ring vacuum pump can operate economically in the range of 0.7 ~ 4kPa suction pressure. Compared with the former two kinds of air extraction devices, it can save more than 70% energy.

1. Water ring vacuum pump of form

According to different characteristics, water ring vacuum pump has different structure forms. Common are: single-stage single acting water ring vacuum pump, single-stage double acting water ring vacuum pump and water ring pre air extractor vacuum pump group.

The unit of Beilun Power Plant adopts a combined vacuum device composed of a single-stage single acting water ring vacuum pump and a pre air extractor. The so-called single-stage single action refers to that there is only one impeller in the vacuum pump, and the suction and exhaust are once respectively in the impeller rotation cycle. Its characteristics are: the section of the vacuum pump body is circular, the structure is simple, the manufacturing capacity is high, the vacuum degree can be obtained, the operation is stable, the noise is small, but the radial force can not be automatically balanced.

2. Water ring vacuum pump of structure

Water ring vacuum pumps are single-stage single acting water ring pump structure, both sides of the impeller simultaneously suction and exhaust. The impeller is eccentrically placed in a chamber composed of a side cover and a vacuum pump body, and the impeller blade is of a forward curved type. Both ends of the shaft are respectively supported by rolling thrust bearings installed in the bearing frame. One end of the shaft is connected to the motor with a rigid coupling. The shaft seal device is a packing shaft seal, and a shaft sleeve is installed at the contact part between the shaft and the packing to prevent the vacuum pump shaft from corrosion and wear.

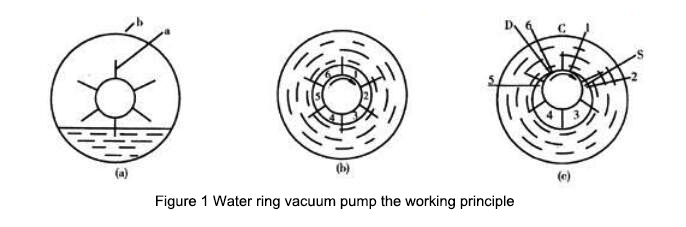

3. Water ring vacuum pump of working principle

The working principle of water ring vacuum pump can be illustrated in Figure 1. When the radial impeller is running in the partially filled shell, due to the centrifugal force, the water is thrown around, as shown in Figure 1 (b), forming a concentric water ring, which is divided into six small water chambers by six blades, so the gas in the small water chamber will not be expanded or compressed. However, when the impeller is installed in the eccentric position as shown in Fig. 1 (c), the volume of the blade chamber 1-3 is gradually expanded, which results in the suction process starting from the connection point C and passing through the suction section s; on the other hand, the volume of the blade chamber 4-6 gradually shrinks with the rotation of the impeller, which constitutes the exhaust process of the gas passing through the extrusion section D. It can be seen that the work of water ring vacuum pump can be divided into three processes: suction, compression and exhaust. Water ring vacuum pump is based on the change of the volume of the blade chamber to suction and exhaust.

4. Water ring vacuum pump set of joint working principle

When the water ring vacuum pump operates in the low vacuum range, it has the ability to vacuum pump a large number of gases efficiently, which is its outstanding advantage. However, because the characteristics of the vacuum pump are affected by the seal water temperature, the maximum vacuum degree can be obtained depends on the vaporization pressure corresponding to the seal water temperature. It is impossible to further improve the vacuum degree. Therefore, when a high vacuum is needed, the inlet pipe of the water ring vacuum pump should be connected in series with a pre air extractor to further improve the vacuum.

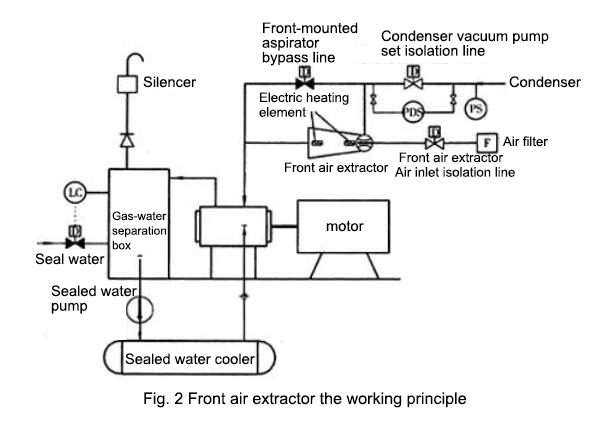

The air is used as the working medium of the front air extractor, and no steam or compressed air is required, as shown in Fig. 2. Its joint working principle is: before the vacuum of the condenser is established, the water ring vacuum pump directly vacuumizes the condenser through the isolation valve at the inlet of the vacuum pump group and the bypass valve of the front air extractor. At this time, the air inlet isolation valve of the front air extractor remains closed. When the vacuum at the inlet of the vacuum pump group reaches a certain vacuum – 72kpa, the bypass valve of the front air extractor automatically interlocks and closes, and the front vacuum pump group reaches a certain vacuum – 72kpa The air inlet isolation valve of the air extractor is automatically interlocked and opened, and the front air extractor is in series working state.

5. water ring vacuum pump of characteristic curve and parameters

The characteristics of the water ring vacuum pump are related to the state of the delivered gas, the temperature and properties of the sealing water. Generally, only the characteristic curves under the specified conditions (atmospheric pressure, gas temperature 30-40 ℃, working water temperature 20 ℃) are given. When the actual conditions are inconsistent with the specified conditions, the vacuum pump characteristics shall be converted or corrected. Characteristic curve of water ring vacuum pump in power plant.

Operation procedure of water ring vacuum pump set of condenser

(1) Check and adjust the vacuum pump set of condenser and its pipeline valve to be in the state before starting, and the water injection of the system has been completed.

(2) Press the condenser vacuum pump set on the CRT screen of the central control room.

(3) After confirming that the sealing water pump of the vacuum pump of the condenser is started, the vacuum pump of the condenser will start automatically

(4) Confirm that the isolation valve at the inlet of the vacuum pump set of the condenser is opened automatically, and the bypass valve of the front air extractor is opened automatically, and the vacuum pump set of the condenser enters the initial vacuum pumping state.

(5) When the condenser vacuum (i.e. the value at the pressure switch PS in Fig. 2) is higher than – 72 kPa, the bypass valve of the front air extractor will automatically close, and the air inlet isolation valve of the front air extractor will automatically open, and the front air extractor will enter into the series working state. The vacuum pump group of condenser will enter into normal operation state.

(6) According to the requirements, put other 3 sets of condenser vacuum pump sets into operation in sequence according to the above steps.

6. Water ring vacuum pump set of condenser of operation condition and precautions

4 sets of vacuum pumps of condenser are put into operation when the unit is initially vacuumized during cold start-up, and the required vacuum can be established in 25 minutes. Then, one set of vacuum pump unit is shut down for high and low pressure condenser respectively. When the vacuum pump unit is shut down, the air of its pre air extractor enters the isolation valve and the isolation valve at the inlet of the vacuum pump unit are automatically closed, and the vacuum pump unit is put into normal standby state.

The condenser vacuum system and water ring vacuum pump set are in good condition, no major problems are found. Only when the atmospheric temperature is lower than 10 ℃ in winter, when the vacuum pump group is switched regularly, (the water inlet valve of the cooler can be adjusted), the throat of the pre air extractor of the vacuum pump group put into operation when the switch occurs is quite serious, which causes the pre air extractor to work abnormally, the air is inverted into the condenser and affects the vacuum of the condenser, and then the two groups of electricity installed on the shell of the pre air extractor are put into operation After 30 minutes of heating element, the system returns to normal. Therefore, when the vacuum pump unit is in standby in winter, the electric heating element of the front air extractor shall be put into operation to ensure the reliable standby of the vacuum pump unit of the condenser.