Water vapor jet vacuum pump for the production of titanium dioxide by sulfuric acid method

In the production of titanium dioxide by the sulfuric acid method, vacuum freezing and crystallization of ferrous sulfate is a new process technology. As the design and manufacturing unit of the steam jet vacuum pump in this set of equipment, in this article, we will combine this work practice, and according to the technological characteristics of the vacuum crystallization of ferrous sulfate, the configuration of the steam jet vacuum pump and the determination of the main performance indicators Give a rough introduction to other issues.

1.Steam jet vacuum pump of introduction

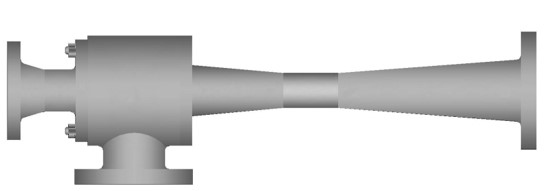

The water vapor jet vacuum pump is a fluid pump composed of single-stage or multi-stage independent steam jets in series with intermediate condensers with medium and high-pressure water vapor as the working power. The working vacuum range of each steam ejector is different.

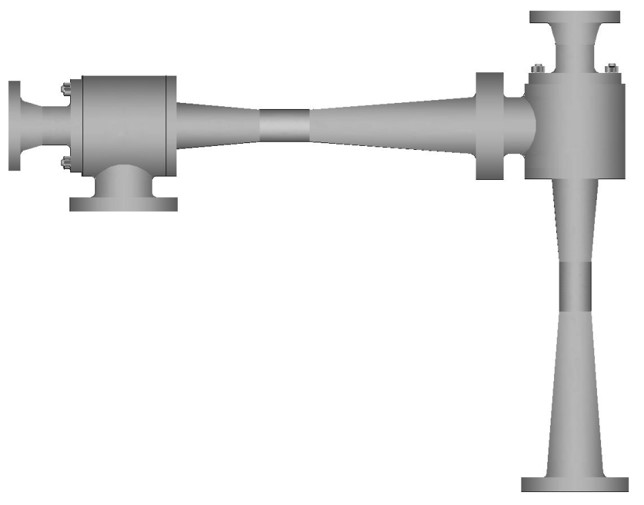

A two-stage water ring vacuum pump can be used to replace the first stage or the first and second stages of the steam jet pump to form a steam jet pump-water ring pump series unit.

2.Steam jet pump for vacuum crystallization of Composition (configuration)

The crystallization process of ferrous sulfate requires that the temperature of the titanium liquid be reduced to about 13~15°C. In this way, the pressure in the vacuum crystallization tank is required to be reduced to 7~10mmHg. To meet this requirement, the steam jet pump must be at least a 3-stage pump. It has the following configuration methods:

(1).A single-stage steam ejector (third stage) is connected in series with an intermediate condenser and a two-stage water ring pump:

At present, the vacuum pump systems of imported equipment are all prepared by this method, but there are the following shortcomings:

a.After a two-stage water ring pump has been used for a period of time, its working vacuum is difficult to ensure to reach 50mmHg, so frequent maintenance is necessary.

b.During each maintenance interval, the working performance of the water ring pump has a process from good to worse, which makes the working efficiency of the steam ejector gradually decline, resulting in unstable production conditions (sometimes, causing the steam ejector to emit Screaming).

c.When the temperature of the titanium solution drops to 34~30°C (corresponding to a vacuum of about 40~30mmHg), the crystal nucleus of ferrous sulfate begins to form. At this time, the temperature should not drop too fast, otherwise, too many crystal nuclei will cause particles too thin. The vacuum pump using this configuration method is difficult to meet this process requirement.

(2).Two-stage steam ejector (third and second stage) in series with two intermediate condensers and a two-stage water ring pump:

We have adopted this configuration method, which has the following advantages:

a.Reduce the working vacuum requirements of the water ring pump (100mmHg is enough); reduce the maintenance workload of the water ring pump.

b.The production status is stable. The auxiliary injection (second stage) can not only automatically adjust the balance between the main injection (third stage) and the water ring pump, but also eliminate the influence of changes in the cooling water temperature within a certain range.

c.Conducive to the control of the temperature drop rate of the titanium solution during the production process. When the titanium liquid temperature is 34~30°C, we can turn on the water ring pump and auxiliary spray instead of the main spray.

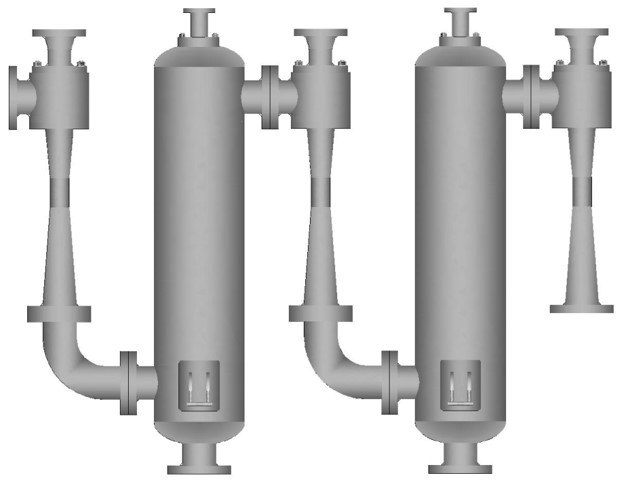

(3).The three-stage steam ejector is connected in series with two intermediate condensers:

This is the conventional configuration of the three-stage steam jet pump, which can fully meet the needs of ferrous sulfate vacuum crystallization. It has no relative moving parts and no maintenance at all (except for serious scaling and corrosion).

In summary, we believe that in the vacuum crystallization of ferrous sulfate, the configuration of the water vapor jet vacuum pump should adopt the latter two methods.

3.The determination of the main performance parameters of the vacuum pump (feeding volume 26M3/tank

1.Water ring pump or first-stage ejector:

The main function of the water ring pump or the first-stage ejector is to pump non-condensable gases. In the production process, the main source of non-condensable gas is the leakage of the system. According to the volume of the entire system (about 70M3), we believe that the leakage can be considered as 30㎏/hr. Based on this, the water ring pump model can be selected as 2SK-12 or 2BE-153 (motor power is 22 kW). Similarly, the first-stage ejector is also designed with 30㎏/hr pumping capacity, and the working steam consumption is about 150 ㎏/hr.

2.Auxiliary ejector (second-stage ejector)

The function of the auxiliary ejector is to increase the vacuum degree in the crystallizer above 40mmHg on the basis of the water ring pump or the first-stage ejector. In this process, the temperature of the titanium liquid will drop to about 34~30°C, and the amount of vaporized water vapor is about 630㎏, but most of it is condensed by the main condenser. The auxiliary ejector sucks non-condensable gas (30㎏/hr) and saturated steam. The total pumping capacity can be considered as 100~170㎏/hr, and the working steam consumption is about 210㎏/hr.

3.Main injector (third stage injector)

The function of the main ejector is to increase the vacuum of the system from 40mmHg to 7~10mmHg, so that the titanium liquid that has formed a crystalline nucleus will continue to cool down from 34~30°C to 13~15°C. During this period, the amount of vapor that the titanium liquid will evaporate is about 1400㎏. To extract this vapor, the amount of working steam required for the main spray is about 2105㎏.

If we require the working time of the main jet to be 50, 60, 70 or 80 minutes respectively, the average pumping volume per unit time of the main jet can be 1680, 1400, 1200 or 1050 kg/hr (that is, the main jet The size of the device may vary accordingly); the corresponding steam consumption per unit time is 2524, 2100, 1800 or 1580㎏/hr.

The above is the configuration of the water vapor jet vacuum pump. The main performance indicators are determined and introduced. For more information, please click to contact us.