What types of vacuum pumps are commonly used for vacuum chucks?

Vacuum suction cup adopts the principle of the vacuum, vacuum negative pressure to “adsorption” artifacts in order to achieve the purpose of handling equipment, vacuum adsorption transmission technology is a very easy to master, using vacuum pump to adjust, control and monitoring, it can effectively improve the workpiece in automatic, semi-automatic production and parts, reduces the work difficulty and improve the working efficiency. Moreover, vacuum adsorption is clean, stable, reliable, and does not damage the surface of the adsorbed object. Vacuum adsorption is widely used in the production and life, then as the main components of vacuum sucker vacuum pump what kinds of types?

Rotary vane vacuum pump

Rotary vane vacuum pump is a common sucker, it has a high degree of vacuum, pumping efficiency and better gas ballast, and favored by some sucker factory.

| Model | Pump speed(m3/h) | Motor Power(KW) | Inlet Diam (inch) | Rotary speed(rpm) | Oil Capacity(L) | G.W(kg) | NoisedB (A) | Dimensions(mm) | |

| 50HZ | 60HZ | ||||||||

| SV-010 | 10 | 12 | 0.37 (3ph)0.55 (1ph) | G1/2 | 1400 | 0.5 | 20 | 64 | 405*253*210 |

| SV-020 | 20 | 24 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 20 | 64 | 405*253*210 |

| SV-025 | 25 | 30 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 22 | 64 | 405*253*210 |

| SV-040 | 40 | 48 | 1.5 (3ph)2.2 (1ph) | G11/4 | 1400 | 1.0 | 50 | 67 | 660*300*270 |

| SV-063 | 63 | 75 | 2.2 | G11/4 | 1400 | 2.0 | 83 | 68 | 695*420*295 |

| SV-100 | 100 | 120 | 3.0 | G11/4 | 1400 | 2.0 | 87 | 72 | 735*420*295 |

| SV-160 | 160 | 192 | 4.0 | G2 | 1400 | 4.5 | 152 | 74 | 805*520*410 |

| SV-200 | 200 | 240 | 5.5 | G2 | 1400 | 4.5 | 159 | 76 | 825*520*410 |

| SV-250 | 250 | 300 | 7.5 | G2 | 1400 | 7.0 | 230 | 76 | 1000*550*410 |

| SV-300 | 300 | 360 | 7.5 | G2 | 1400 | 7.0 | 236 | 76 | 1200*550*410 |

| SV-630 | 630 | 750 | 15.0 | DN100 | 960 | 35 | 620 | 75 | 1630*1300*980 |

| SV-750 | 750 | 900 | 18.5 | DN100 | 1150 | 35 | 640 | 76 | 1630*1300*980 |

Water ring vacuum pump

Water ring vacuum pump is also commonly used in the vacuum sucker, water ring vacuum pump has high extraction rate, good gas ballast performance, stainless steel corrosion resistance, so the vacuum sucker is often equipped with water ring vacuum pump.

| Curve No. | Model | Max. suction capacity | Ultimate vacuum mbar(MPa) |

Motor power kW |

Speed r.p.m |

Operating liquidflow rate L/min |

Noise dB(A) |

Weight kg |

|

| m3/min | m3/h | ||||||||

| 60V | 2BV2-060 | 0.45 | 27 | 33mbar (-0.097MPa) |

0.81 | 2840 | 2.5 | 62 | 37 |

| 61V | 2BV2-061 | 0.86 | 52 | 1.45 | 2840 | 2.5 | 65 | 41 | |

| 70V | 2BV2-070 | 1.33 | 80 | 2.35 | 2860 | 3 | 66 | 66 | |

| 71V | 2BV2-071 | 1.83 | 110 | 3.85 | 2880 | 4.7 | 72 | 85 | |

| 110V | 2BV5-110 | 2.75 | 165 | 4 | 1440 | 7.2 | 63 | 120 | |

| 111V | 2BV5-111 | 3.83 | 230 | 5.5 | 1440 | 8.8 | 68 | 150 | |

| 121V | 2BV5-121 | 4.66 | 280 | 7.5 | 1440 | 11 | 69 | 210 | |

| 131V | 2BV5-131 | 6.66 | 400 | 11 | 1460 | 16 | 73 | 280 | |

| 161V | 2BV5-161 | 8.33 | 500 | 15 | 970 | 22 | 74 | 390 | |

| 110V | 2BV6-110 | 2.75 | 165 | 4 | 1440 | 67 | 63 | 150 | |

| 111V | 2BV6-111 | 3.83 | 230 | 5.5 | 1440 | 10 | 68 | 200 | |

| 121V | 2BV6-121 | 4.66 | 280 | 7.5 | 1440 | 12 | 69 | 230 | |

| 131V | 2BV6-131 | 6.66 | 400 | 11 | 1460 | 17 | 73 | 315 | |

| 161V | 2BV6-161 | 8.33 | 500 | 15 | 970 | 23 | 74 | 426 | |

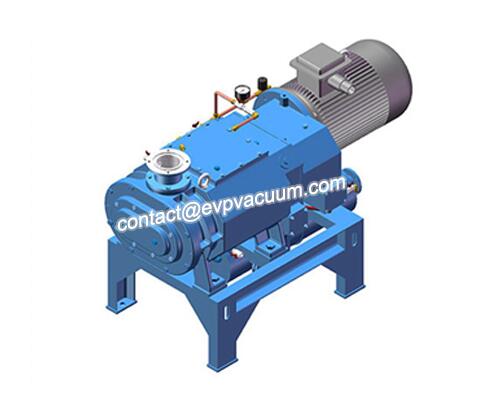

Screw vacuum pump

Screw vacuum pump system is currently the most popular vacuum sucker market one, it looks clean installation, with high efficiency, good energy efficiency, stable operation and low noise and other characteristics, there are often customers for the old pump reconstruction program, with a screw vacuum pump to replace several pumps water ring pump or rotary vane pump operation, super save electricity.

| Model | Unit | LG50 | LG70 | LG100 | LG150 | LG200 | LG300 | LG350 | ||

| Suction Capacity | 50 Hz | m³/hr | 180 | 250 | 360 | 540 | 720 | 1080 | 1260 | |

| 60 Hz | 216 | 300 | 430 | 650 | 850 | 1296 | 1512 | |||

| Ultimate Pressure | 50 Hz | mbar | 0.02 | |||||||

| 60 Hz | 0.01 | |||||||||

| Motor power | 50 Hz | Kw | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | |

| 60 Hz | 7.5 | 11 | 15 | 15 | 22 | 26 | 26 | |||

| Rotary Speed | 50 Hz | RPM | 2900 | |||||||

| 60 Hz | 3550 | |||||||||

| Inlet diam | mm | 50 | 65 | 70 | 90 | 100 | 100 | 100 | ||

| Outlet diam | mm | 40 | 40 | 55 | 65 | 65 | 65 | 65 | ||

| Lubricating oil consumption | L | 0.85 | 0.85 | 1.4 | 2 | 2 | 2 | 2 | ||

| Cooling water consumption | L/min | 2.5 | 2.6 | 2.8 | 3 | 4 | 4 | 4 | ||

| gal/min | 0.67 | 0.7 | 0.75 | 0.8 | 1.07 | 1.07 | 1.07 | |||

| Weight | Kg | 295 | 350 | 480 | 520 | 680 | 850 | 850 | ||

| Noise | dB(A) | 68 | 70 | 70 | 72 | 74 | 84 | 84 | ||

| Working temperature | ℃ | 5~40 | ||||||||

| Max. Permissible humidity | / | 90% | ||||||||

The above three vacuum pumps are the vacuum pumps commonly used in vacuum suckers. Some customers will ask which one is better to use. This needs to be selected according to the actual situation. Vacuum pump as the main components of vacuum chuck, in order to maximize efficiency, must be careful selection! Finally, I would like to remind you of the use of vacuum pumps in CNC suckers. After starting the vacuum pump, the vacuum pump will remove the air in the vacuum sucker through rubber pipes and filters, forming a vacuum in the vacuum sucker. The external atmospheric pressure will press the indexable carbide blade on the vacuum sucker. At this point, the surface grinding machine can be used to grind the indexable blade. Because the blade has a gap between bottom and vacuum suction cup lid in the grinding process of dust through the clearance is pumped into the filter, after filter of the dust in the gas filtering, vacuum air pump people clean, otherwise the hardness of high dust into the vacuum pump, will make the vacuum pump damage and even can’t work, so it must pay attention!

What do you know about rotary vane vacuum pumps?

Rotary vane vacuum pump is a kind of variable capacitance mechanical vacuum pump which can obtain vacuum by using the rotary motion of the rotor and the rotary vane which can slide in the rotor groove. When using the working fluid to lubricate and fill the dead space of the pump chamber, separating the exhaust valve and the atmosphere, it is usually called the oil seal rotary vane vacuum pump. Rotary vane vacuum pump, the pump and the motor directly connected or connected with a coupling called direct rotary vane vacuum pump. In each kind of pump, also has the single stage and the double stage divides.

In the single-stage pump, due to the choice of structure and parameters, the pump limit pressure and use is different. Rotary vane vacuum pump has been widely used and constantly improved. In terms of pump structure, in order to prevent oil return when the pump stops, some are equipped with a check valve that can automatically cut off the oil circuit, some are equipped with a cut-off valve for the air inlet passage, and some are equipped with a pump and control structure to automatically cut off the gas circuit to keep the pump port in a vacuum state when the pump turns on the gas ballast and suddenly goes dark.

In terms of accessories, there are mist eliminator, odor filter, population filter, dust filter, steam condensation trap, chemical trap for blocking debris such as broken glass, and temperature control water volume regulating valve for controlling pump temperature to improve water vapor extraction rate and protect the pump. Speaking of the rotary vane vacuum pump, in fact, it is very familiar to many people, probably because of its variety, distribution is very wide. Rotary vane vacuum pump, vacuum pump usually have dry screw vacuum pump.

Water ring vacuum pump, reciprocating vacuum pump, rotary vane vacuum pump and other types. With the development of science and technology, the vacuum pump is widely used. Rotary vane vacuum pump USES eccentric rotor to drive the vane when the volume of different Chambers in the pump changes so that the internal pressure changes, rotary vane vacuum pump. Is the most widely used vacuum pump, and in this rotary vane vacuum pump another kind of work accessories products – vacuum pump oil role is also crucial. Rotary vane vacuum pump oil if the product quality is poor or mixed with impurities of the product will flow with the pump internal scratches and corrosion, and the vacuum pump.

The main product of vacuum pump is rotary vane vacuum pump, which seriously affects its working level and efficiency.

Rotary vane vacuum pump is also known as multi-chamber rotary vane vacuum pump, because its blade vacuum pump body is divided into three Chambers. As the medium to obtain vacuum, rotary vane vacuum pump oil plays the role of lubrication, cooling and sealing in the vacuum pump, which also shows the importance of rotary vane vacuum pump oil to the whole body operation.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)