Scroll Vacuum Pump for Sputtering Equipment

Sputtering Equipment Products of Overview

The equipment combines magnetron sputtering technology with vacuum evaporation technology in the same coating equipment. It not only uses magnetron sputtering cathode glow discharge to sputter target atoms and partially ionize and deposit them on the substrate to form a film, but also uses resistance heating to melt the metal plating in vacuum and vaporize and deposit them on the substrate to form a film.

Magnetron sputtering/vacuum evaporation composite coating equipment combines magnetron sputtering technology and vacuum evaporation technology in the same vacuum coating equipment. It not only uses magnetron sputtering cathode glow discharge to sputter target atoms and partially ionize and deposit them on the substrate to form a film, but also uses resistance heating to melt and deposit metal plating materials in vacuum. It is vaporized and then deposited on the substrate to form a film.

Increased use and flexibility of equipment. The equipment is applied to metallize plastic surface such as mobile phone shell, and to deposit non-conductive film and electromagnetic shielding film.

The equipment is equipped with plasma treatment device, high efficiency magnetron sputtering cathode and resistance evaporation device, etc. The equipment has fast deposition rate, good adhesion of coating, fine and compact coating, high surface finish and good uniformity. The machine realizes automatic control of coating process, large loading capacity, reliable operation and qualified rate. High, low production cost, green environmental protection. The equipment is mainly used in computer case, mobile phone case, household appliances and other industries. It can be coated with metal film, alloy film, composite film, transparent (translucent) film, non-conductive film, EMI electromagnetic shielding film, etc.

Next, we introduce the scroll vacuum pump for sputtering equipment.

The working principle of the scroll vacuum pump:

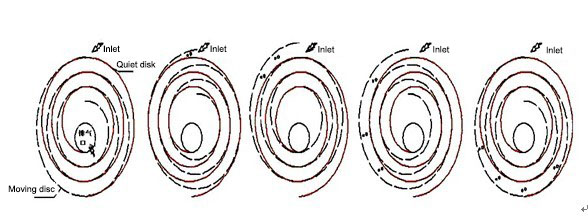

The scroll vacuum pump is composed of two involute spiral curve discs, namely a static scroll disc and a moving scroll disc. When the moving scroll is installed eccentrically, the static scroll and the moving scroll form a lunar bud cavity. With the rotating scroll, the lunar bud-shaped cavity continuously rotates and compresses inward, and finally discharges from the middle to the outlet. The rotating scroll disc runs continuously, and the gas is continuously inhaled and compressed from the intake port, and discharged from the outlet to form a vacuum.

Connection between scroll vacuum pump and vacuum system:

1. The inlet (flange) of the pump is KF40, and the outlet (flange) is KF25.

2. Generally, the inlet of the pump is directly connected with the vacuum chamber, but the premise is clean gas.

3. If there are debris, water vapor, dust and so on, it is suggested to use the following figure to connect.

4. Install the isolation valve between the vacuum chamber and the inlet of the pump to prevent debris from being pumped back into the vacuum chamber when starting or stopping.

5. We recommend the use of automatic valves as isolation valves, which close when the power supply fails to prevent debris from being pumped back into the vacuum chamber from the inside of the pump.

6. Install an inflatable valve between the isolation valve and the inlet of the pump. Open the inflatable valve during the operation of the system to remove dirt and water vapor in the pump.

7. Clean connections should be used between the vacuum chamber and the vacuum pump. We recommend that hoses be used between the inlet of the pump and the vacuum chamber so that the vibration of the pump does not propagate to the vacuum chamber.

8. Ensure that the exhaust pipe is not blocked during operation.

9. Ensure that the outlet pressure of the pump does not exceed atmospheric pressure.