vacuum pump for sale

EVP vacuum technology co., ltd. is a professional vacuum pump sales, installation, maintenance of manufacturers, the company’s main water ring vacuum pump, vane vacuum pump, screw vacuum pump, roots vacuum pump,dry scroll vacuum pump, molecular vacuum pump, diffusion pump, piston pump, water supply equipment, water pump accessories and other products.

Here is one of our company’s popular products:

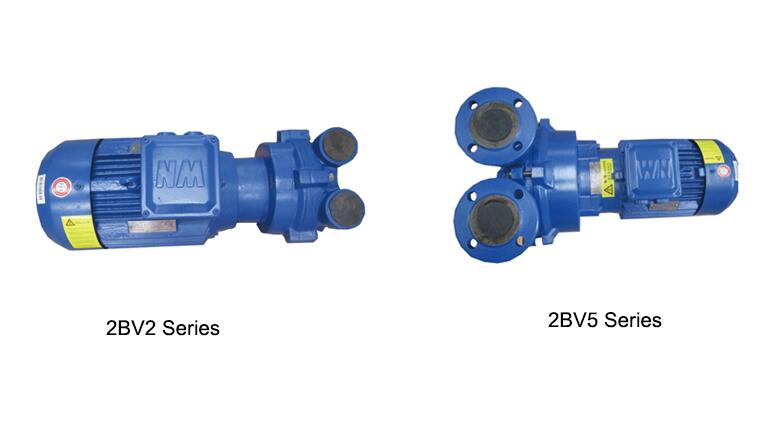

2BV series water ring vacuum pump

2BV series water ring vacuum pump is based on the traditional vacuum pump in China. It USES the machine pump coaxial direct connection type design, the reliability is high, easy to install and maintain, less than the traditional vacuum pump volume 30%. Mechanical seals eliminate leakage. The 50% working fluid of the steam separator can be recycled to reduce the pollution and the operation cost. The bronze impeller is used to improve the corrosion resistance of the pump. According to the requirements of the user, the use of stainless steel material, the pump will operate in bad conditions.

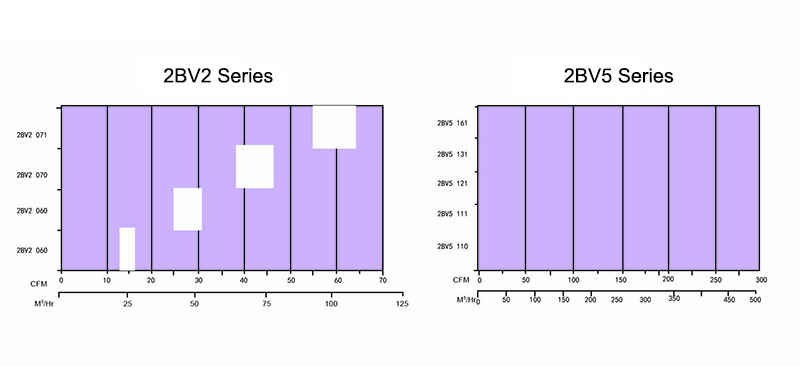

Performance range

Product specifications:

| Curve No. | Model | Max. suction capacity | Ultimate vacuum mbar(MPa) |

Motor power kW |

Speed r.p.m |

Operating liquidflow rate L/min |

Noise dB(A) |

Weight kg |

|

| m3/min | m3/h | ||||||||

| 60V | 2BV2-060 | 0.45 | 27 | 33mbar (-0.097MPa) |

0.81 | 2840 | 2.5 | 62 | 37 |

| 61V | 2BV2-061 | 0.86 | 52 | 1.45 | 2840 | 2.5 | 65 | 41 | |

| 70V | 2BV2-070 | 1.33 | 80 | 2.35 | 2860 | 3 | 66 | 66 | |

| 71V | 2BV2-071 | 1.83 | 110 | 3.85 | 2880 | 4.7 | 72 | 85 | |

| 110V | 2BV5-110 | 2.75 | 165 | 4 | 1440 | 7.2 | 63 | 120 | |

| 111V | 2BV5-111 | 3.83 | 230 | 5.5 | 1440 | 8.8 | 68 | 150 | |

| 121V | 2BV5-121 | 4.66 | 280 | 7.5 | 1440 | 11 | 69 | 210 | |

| 131V | 2BV5-131 | 6.66 | 400 | 11 | 1460 | 16 | 73 | 280 | |

| 161V | 2BV5-161 | 8.33 | 500 | 15 | 970 | 22 | 74 | 390 | |

| 110V | 2BV6-110 | 2.75 | 165 | 4 | 1440 | 67 | 63 | 150 | |

| 111V | 2BV6-111 | 3.83 | 230 | 5.5 | 1440 | 10 | 68 | 200 | |

| 121V | 2BV6-121 | 4.66 | 280 | 7.5 | 1440 | 12 | 69 | 230 | |

| 131V | 2BV6-131 | 6.66 | 400 | 11 | 1460 | 17 | 73 | 315 | |

| 161V | 2BV6-161 | 8.33 | 500 | 15 | 970 | 23 | 74 | 426 | |

Application:

Widely used in chemical, pharmaceutical, food, paper steel and other industries.

In addition to the standard pump/motor unit, we offer a full range of 2BV units, including steam separators, heat exchangers and cavitation-protected linkers. In addition, it can also be integrated with other vacuum equipment such as roots pump vacuum series. With the powerful advantages of EVP in vacuum pump, motor and electrical control, we can provide system solutions for users.

The rotating part of 2BV, the impeller, rotates the working fluid to form a liquid ring in the oval pump. At this time, the working fluid plays the role of sealing medium, compression medium and cooling medium at the same time, without wear and lubrication. Because the impeller is eccentric relative to the rotating liquid ring. The fluid moves back and forth in the space between the blades, just as the piston moves in the cylinder, exerting a suction and compression effect on the pumping medium. In the exhaust stage, the liquid ring gradually away from the tire, pumping medium along the axis from the exhaust outlet. In the suction stage, the impeller gradually away from the tire, pumping medium along the axis from the suction port suction. A continuously injected supplemental fluid to compensate for the fluid carried away by the exhaust gas.

All the design features of the 2BV series make it essentially maintenance-free. Oil-free design, no oil, of course, also do not need to replace the oil filter equipment. In normal use, the average bearing only needs to be greased once every 5 years. Under normal operating conditions, 2BV mechanical seals do not require regular adjustment as packing seals.

2BV series water ring vacuum pump video

The above is small make up for you to introduce the 2bv series of vacuum pumps, our company’s best-selling products also include roots vacuum pump and rotary vane vacuum pump, if interested can click on the following products, see the details of specific products or give us a message.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)