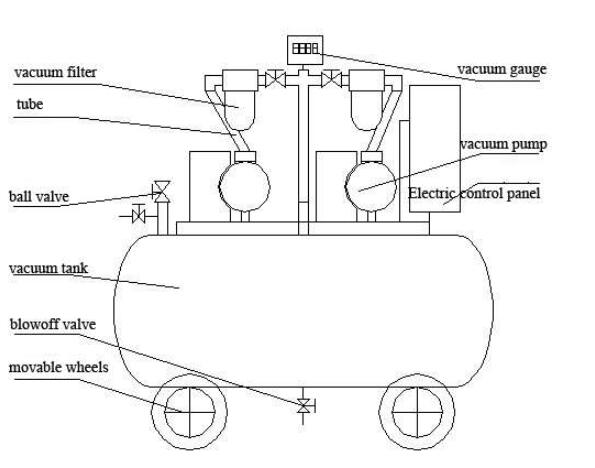

Vacuum pump system

CVS vacuum pump system

SV rotary vane pump working principle

Volume reduction and pressure increase is the principle of rotary operation. This kind of static design can produce good results in the application of vacuum, pressure and the combination of the two. According to specifications and construction, such as oil lubricated or oil-free type, the vacuum degree can be up to 0.1mbar, flow from 3 to 1535m3/hr; Pressure up to 1.5bar, flow from 3 to 155m3/hr. When applied to both vacuum and pressure, both 0.6bar vacuum and 0.7bar positive pressure can be achieved. In the cylindrical pump chamber, the rotor is mounted eccentrically, almost in contact with the cylinder near the top, and the rotor blades are mounted in numerous rotor slots. When the rotor starts to rotate, the blades slide along the inside of the cylinder after being thrown out by centrifugal force. In this way, an air chamber is formed between the two blades, whose volume changes constantly with rotation. When the rear blade reaches the air inlet, the gas enters the air chamber from the air inlet. At this time, the air chamber reaches its maximum volume.

As the chamber moves, its volume becomes smaller and smaller, and the gas is compressed, the pressure increases, until the pressure of the gas in the chamber exceeds the pressure in the pressure chamber, and the gas is discharged from the air outlet. Some models are equipped with a check valve to prevent the return of the gas discharged when the extreme pressure is reached. When operating as a vacuum pump, the process is the same, but the air chamber provides negative pressure and the chamber body is atmospheric pressure.

Vacuum pump system brief introduction:

By two or more vacuum pumps and other accessories combination of a system to complete the need to achieve the goal of vacuum pump system vacuum pump system design is the key problem is the choice of vacuum pumping unit of the main pump main pump type determination

1. Determine the type of main pump according to the ultimate pressure required by the vacuum chamber. In general, the ultimate pressure of the main pump is half to one order of magnitude lower than that of the vacuum chamber.

2. Select the main pump according to the working pressure required by the vacuum chamber in process production. Should correctly choose the working point of the main pump, in its working pressure range, should be able to exclude all the gas produced in the process of the vacuum chamber. Therefore, the working pressure of the vacuum chamber must be within the range of the optimal pumping speed of the main pump.

3. Select the main pump according to the volume size of the vacuum chamber and the required pumping time. The volume of the vacuum chamber has an effect on the time from the system to the limit vacuum. When the pumping time is fixed, the larger the volume of the vacuum chamber is, the higher the pumping speed of the main pump will be.

4, the correct combination of vacuum pump, because the vacuum pump has selective pumping, so sometimes choose a pump can not meet the requirements of pumping, need several pump combination, mutual supplement to meet the requirements of pumping.

5, if the vacuum system strictly requires no oil, it should choose a variety of non-oil pump as the main pump. If the requirements are not strict, you can choose

Oil pump, and then add some anti-oil pollution measures, such as cold trap, baffle, oil trap, etc., can also meet the requirements of clean vacuum.

6. When selecting a vacuum pump, the composition of the gas to be pumped should be known, and the corresponding pump should be selected for the composition of the gas to be pumped. If the gas contains corrosive gas, particle dust, it should be considered to choose dry vacuum pump, corrosion resistant vacuum pump. Or install auxiliary equipment in the inlet pipe of the pump.

7. Choose the main pump according to the economic indicators such as the initial investment and daily maintenance cost of the whole vacuum system.

CVS vacuum pump main application industry: circuit board, blister, vacuum molding, fixture, etc. CVS vacuum pump in the above industry application technology mature, is the preferred vacuum pump for most customers; High technical requirements for the product, the vacuum pump flow requirements in 180-200m3/h, vacuum degree (suction) more than 50pa; The CVS vacuum pump is equipped by kaixu. After years of use, the failure rate of the vacuum pump is extremely low, and there are no problems like stuck or sudden failure. The quality of the CVS vacuum pump is stable, and its warranty is more than 5 years.

Technical parameters

| Size | Speed(m3/h) | Vacuum pump | Pumpquantity | Pressure(MPA) | Vacuum tank(m3) |

| CVS-1X010 | 10 | SV-010 | 1pcs | 0~-0.1 | 0.06-0.2 |

| CVS-1X020 | 20 | SV-020 | 1 pcs | 0~-0.1 | 0.06-0.2 |

| CVS-1X025 | 25 | SV-025 | 1 pcs | 0~-0.1 | 0.06-0.2 |

| CVS-1X040 | 40 | SV-040 | 1 pcs | 0~-0.1 | 0.06-0.2 |

| CVS-1X063 | 63 | SV-063 | 1 pcs | 0~-0.1 | 0.06-0.2 |

| CVS-1X100 | 100 | SV-100 | 1 pcs | 0~-0.1 | 0.06-0.2 |

| CVS-1X160 | 160 | SV-160 | 1 pcs | 0~-0.1 | 0.3-2 |

| CVS-1X250 | 250 | SV-250 | 1 pcs | 0~-0.1 | 0.3-2 |

| CVS-1X300 | 300 | SV-300 | 1 pcs | 0~-0.1 | 0.3-2 |

| CVS-2X010 | 20 | SV-010 | 2 pcs | 0~-0.1 | 0.06-0.3 |

| CVS-2X020 | 40 | SV-020 | 2 pcs | 0~-0.1 | 0.06-0.3 |

| CVS-2X025 | 50 | SV-025 | 2 pcs | 0~-0.1 | 0.06-0.3 |

| CVS-2X040 | 80 | SV-040 | 2 pcs | 0~-0.1 | 0.06-1 |

| CVS-2X063 | 126 | SV-063 | 2 pcs | 0~-0.1 | 0.3-2 |

| CVS-2X100 | 200 | SV-100 | 2 pcs | 0~-0.1 | 0.3-2 |

| CVS-2X160 | 320 | SV-160 | 2 pcs | 0~-0.1 | 0.5-2 |

| CVS-2X250 | 500 | SV-250 | 2 pcs | 0~-0.1 | 0.5-2 |

| CVS-3X100 | 100 | SV-100 | 3 pcs | 0~-0.1 | 0.5-2 |

| CVS-3X160 | 480 | SV-160 | 3 pcs | 0~-0.1 | 0.5-2 |

| CVS-3X250 | 750 | SV-250 | 3 pcs | 0~-0.1 | 0.5-2 |

| CVS-3X300 | 900 | SV-300 | 3 pcs | 0~-0.1 | 0.5-2 |

Pump system components specification:

Related links: vacuum valeves, vacuum parts.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)