various vacuum process technologies under different vacuum conditions

Application overview of various vacuum process technologies under different vacuum conditions

As the density of gas molecules in the gaseous space decreases, the physical properties of the gas change significantly. Based on this change in gas properties, people use various vacuum processes under different vacuum conditions to achieve the purpose of serving production and scientific research.

It can be said that from the manufacture of ultra-large-scale integrated circuits with hundreds of electronic components per square centimeter surface to the operation of large accelerators several kilometers long, from the production of civilian decorations to the advent of controlled nuclear fusion, artificial satellites, and space shuttles, they are all closely related to vacuum process technology.

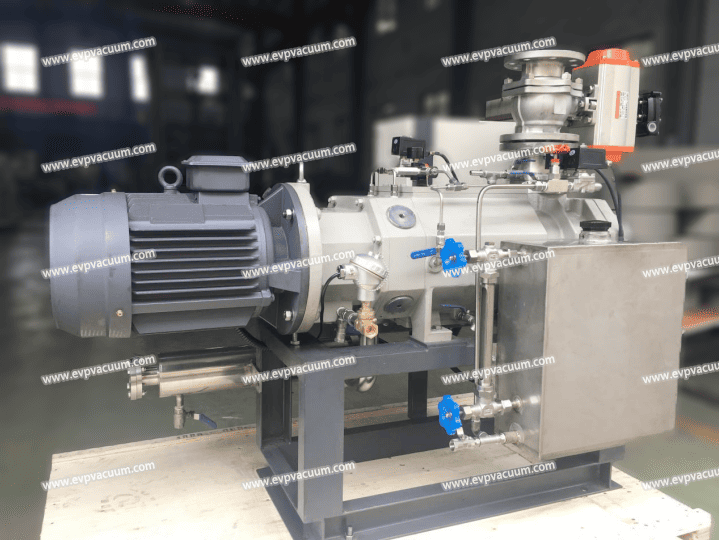

Rough vacuum pump

Vacuum state: Rough vacuum 105 ~103 Pa, 760 ~ 10 Torr

Gas properties: Compared with normal pressure, the gas state only changes from a large number of molecules to a small number, but there is no change in the spatial characteristics of gas molecules. Molecules collide frequently with each other.

Application principle: The mechanical application of vacuum is realized by using the force generated by the pressure difference between vacuum and atmosphere and the principle of uniformity of differential force.

Application Overview; 1. Vacuum suction and transportation of solids, liquids, colloids and particles; 2. Vacuum suction cup lifting, vacuum medical equipment; 3. Vacuum forming, replicating relief; 4. Vacuum filtration; 5. Vacuum impregnation.

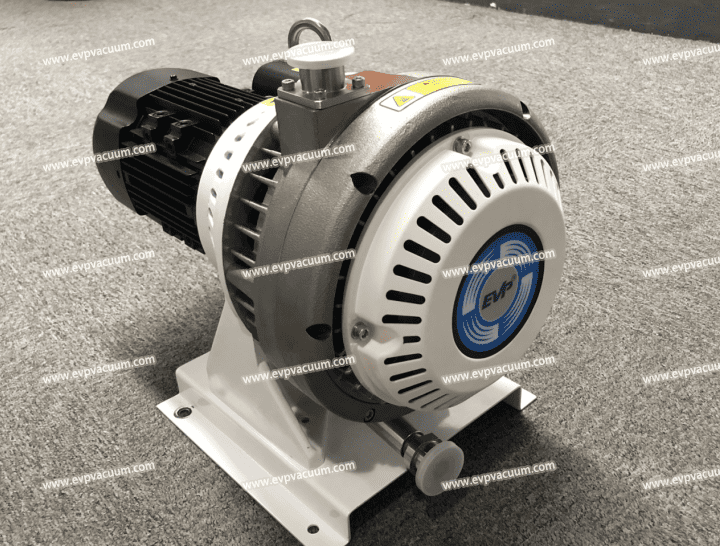

Low vacuum pump

Vacuum state: low vacuum 103~10-1 Pa, 10~10-3 Torr

Gas properties: The collisions between gas molecules and between gas molecules and the wall are similar, and the density of gas molecules is relatively small.

Application principle: Non-oxidative heating can be achieved by reducing the density of gas molecules. Vacuum heat insulation and insulation can be achieved by using the principle that the heat conduction and convection of the gas gradually disappear when the gas pressure decreases. Vacuum freezing and vacuum drying can be achieved by using the principle that the boiling point of the liquid decreases when the pressure decreases.

Application Overview; 1. Vacuum melting, degassing, casting and heat treatment of ferrous metals; 2. Vacuum hot rolling, vacuum surface chromizing; 3. Vacuum insulation and vacuum heat insulation; 4. Vacuum distillation of drugs, oils and polymer compounds; 5. Vacuum freezing and vacuum drying; 6. Vacuum packaging, vacuum inflation packaging; 7. Low-pressure wind tunnel in high-speed aerodynamic experiments

High vacuum pump

Vacuum state: high vacuum 10-1~10-6 Pa, 10-3~10-8 Torr

Gas properties: Molecules rarely collide with each other, but molecules collide with the vessel wall frequently, and the density of gas molecules is low.

Application principle: Vacuum metallurgy, vacuum coating and vacuum device production are carried out by taking advantage of the low density of gas molecules and the weak chemical reaction between any substance and residual gas molecules.

Application Overview; 1. Vacuum melting and refining of rare metals, ultra-pure metals and alloys, and semiconductor materials; vacuum reduction metallurgy of commonly used structural materials; 2. Vacuum distillation and refining of pure metals; evaporation of radioactive isotopes; 3. Vacuum sintering of refractory metals; 4. Vacuum purification and crystal preparation of semiconductor materials; 5. Manufacturing of high-temperature metallographic microscopes and high-temperature material experimental equipment; 6. Vacuum coating, ion implantation, film-etching and other surface modifications; 7. Manufacturing of electro-optical tubes, ion tubes, electron source tubes, beam tubes, electron diffractometers, electron microscopes, X-ray microscopes, various particle accelerators, energy spectrometers, nuclear radiation spectrometers, neutron tubes, and gas lasers in the electric vacuum industry; 8. Electron beam degassing, electron beam welding, zone melting, electron beam heating

Ultra-high vacuum pump

Vacuum state: ultra-high vacuum 10-1~10-6 Pa, 10-1~10-8 Torr

Gas properties: The density of gas molecules is low and the collision with the wall is very rare, which increases the time it takes to form a single molecular layer on the surface. There are only atoms of the solid itself and almost no other atoms or molecules in the gaseous space.

Application principle: Surface physics and surface chemistry research is achieved by using the principle that the density of gas molecules is extremely low and there is very little collision with the surface, and it takes a long time for a single molecular layer to form on the surface.

Application Overview; 1. Research on controlled thermonuclear fusion; 2. Production of time-standard hydrogen molecular mirror; 3. Research on surface physics and surface chemistry; 4. Simulation of the outer space environment; 5. Operation of large-scale synchrotron proton accelerator; 6. Production of electromagnetically suspended high-precision gyroscope.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)