How to Operate and Maintain Liquid Ring Vacuum Pumps

The development of vacuum technology has never stopped, and the most prominent one is the liquid ring vacuum pump. Because of its simple and strong structure, if it can be well maintained, it can continue to provide years of reliable performance.

When you find something unusual about the vacuum pump, the most important thing is to stop the vacuum pump in time and correct the problem. As the owner of the vacuum pump, your initiative may mean whether the life of the vacuum pump is short or long.

Therefore, it is important to check the vacuum pump regularly to ensure it is kept in the best condition. If the problem does occur, immediately stop the vacuum pump to check the problem.

However, to take these steps, it is necessary to understand the components of a liquid ring vacuum pump. This article describes in detail the basic functions, composition, installation and maintenance procedures of the liquid ring vacuum pump.

Liquid ring vacuum pump function

Divided into three simple stages, basically, gas is introduced, pressurized and discharged. The following mainly introduces what kind of function the water tank plays in the vacuum pump:

Liquid ring vacuum pump water tank function

No matter whether the liquid ring vacuum pump is used alone or in the vacuum pump unit, it will require a water tank. What is the role of this water tank? It is actually used to store the working medium water.

The liquid ring vacuum pump is called liquid ring vacuum pump because it uses water as the working medium to generate vacuum. Water is only used as the working medium and will not be consumed in large quantities. A large amount of water will be sprayed out of the air outlet of the vacuum pump. Direct drainage of water will cause a lot of waste of water resources, and the water tank can be stored in the water tank and can be sucked back as a working medium.

It is worth noting that if the vacuum pump is used to suck high-temperature gas or the water tank is too small, a heat exchange device (such as a cooling tower or plate heat exchange device, etc.) needs to be added to the circulating water pipeline to cool the circulating water, because if the working medium water temperature is too high It will affect the vacuum degree of the vacuum pump, and the vacuum degree will be greatly reduced.

Liquid ring vacuum pump of composition

The liquid ring vacuum pump consists of basic parts and accessories.

Liquid ring vacuum pumps of basic components

1. Pump housing: outer cylinder + front and rear cover

2. Impeller: It is composed of impeller and shaft hot-in assembly, and the pump shaft is equipped with a shaft sleeve.

3. Port plate: the front and rear distribution boards are installed between the body and the front and rear side covers.

4. Valve plate components: It is composed of a water blocking plate and a flexible valve plate. It is installed on the exhaust port of the distribution plate and has the function of automatically adjusting the exhaust angle. The flexible valve plate is a vulnerable part, and its material is polytetrafluoroethylene. If it is damaged, it will affect the performance of the liquid ring vacuum pump compressor, and it must be replaced in time.

5. Shaft seal components: packing seal or mechanical seal can be used. There are two cooling methods for shaft seal, one is internal water supply cooling method, the other is external water supply cooling method, purchase different shaft seal water supply methods, shaft seal The installation direction of the body is different.

6. Side cover

7. Bearings: Two angular contact ball bearings are used for axial positioning, and one cylindrical roller bearing bears the radial load.

8. Liquid supply pipeline: Provide working fluid to the liquid ring vacuum pump shrink machine.

9. Shaft seal water supply pipeline

liquid ring vacuum pump accessories of importance

Vacuum pumps are widely used and cannot do without the silent support of vacuum pump accessories. The quality of its accessories is related to the normal operation of the entire equipment and even efficient operation. This shows its importance:

1. Vacuum pump accessories are mainly used in various positions of the vacuum pump body. The vacuum pump is widely used, so it means that the vacuum pump accessories play a vital role.

2. It is the sturdiness and durability of vacuum pump accessories that support the finishing operation of vacuum pumps. Vacuum pumps are so widely used and cannot do without the great contribution made by their accessories. Vacuum pumps are widely used in low temperature equipment, dye chemical industry, electronics industry, brick and tile machinery, paper-making machinery, food machinery, plastic machinery, industrial electric furnaces, vacuum equipment, fertilizers, metallurgy, foundation treatment, mining and other fields.

Vacuum pump accessories are of great significance to vacuum pumps. When purchasing accessories, you must recognize the regular manufacturers and let the vacuum pump operate efficiently to achieve its application effects.

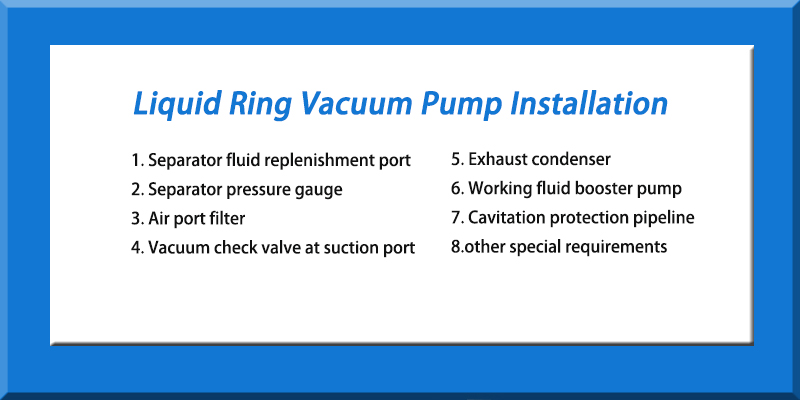

Liquid ring vacuum pump installation

Liquid ring vacuum pump can choose to install accessories

1. Separator fluid replenishment port: if the working fluid is insufficient, the fluid replenishment port can be appropriately refilled with working fluid;

2. Separator pressure gauge: If pressure may be generated in the separator, a pressure gauge should be installed on the separator;

3. Air port filter: If foreign matter may enter the pump in the system and pipeline, a filter or screen should be installed at the suction port of the pump;

4. Vacuum check valve at suction port: In order to prevent backflow when the vacuum pump/compressor stops, it is generally necessary to install a vacuum check valve or pneumatic valve at the inlet of the pump;

5. Exhaust condenser: If you need to capture or recover the condensable gas at the exhaust port, you can install a condenser at the exhaust port of the gas-liquid separator;

6. Working fluid booster pump: If the working fluid supply of the pump is insufficient or the working pipeline resistance is large, a working fluid booster pump can be installed;

7. Cavitation protection pipeline: If the suction pressure of the vacuum pump is close to the saturated vapor pressure of the working fluid, a cavitation protection pipeline should be installed between the vacuum pump and the separator;

8. If there are other special requirements, corresponding accessories can be installed.

What should be paid attention to when maintaining the liquid ring vacuum pump?

Since the liquid ring vacuum pump has brought great convenience to our production and life, we must maintain it in peacetime and perform regular maintenance on it. Then how do we usually maintain the liquid ring vacuum pump? So let’s analyze this problem carefully below.

If during normal use, when a special event occurs, you can see if the exhaust valve plate makes an abnormal sound, but it’s not that the exhaust valve plate is broken. Check whether the impeller The sound of colliding with the distribution. The liquid ring vacuum pump should pay attention to the bearing lubricating oil during normal operation. If the temperature of the bearing exceeds the normal temperature, it means that the bearing should be lubricated.

In fact, there are still many small matters for maintenance attention. I only selected a few key points to talk about, hoping to help you, and we will continue to talk about it in future articles.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)